I have been curing meats at home for almost two ten years now. Time really flies! As many of you know, my initial results seemed encouraging, but then it all quickly went downhill. The biggest problem was the high humidity. I tried many things to fix it, but nothing worked. About a year and a half into my hobby, I made a change to my meat curing chamber - I added a peltier dehumidifier. It helped me start getting consistent and predictable results. I was in charcuterie heaven! My curing frustrations were officially over. Since then, I have implemented a number of additional changes that have made my curing chamber even more consistent, predictable, and versatile. I hope this guide will help you build your dream meat curing chamber, too.

Building a meat curing chamber

Building a meat curing chamber at home is ridiculously simple and will not break the bank. All you need is the (now revised) list of things listed below.

- A full-size frost-free fridge ($60-$120 on Craigslist)

- A temperature controller ($50-$130)

- A humidity controller ($50-$130)

- An ultrasonic humidifier ($30-$50)

- A peltier dehumidifier ($40-$80)

- A heating mat ($10-$30)

Ten years ago, I started off without a dehumidifier. Such a setup works. That is, if all planets line up perfectly or you happen to live in an area that is conducive to meat curing. Otherwise, you are going to face challenges controlling high humidity.

My first meat curing chamber was about as outlined above but with a less-than-perfect controller and without a dehumidifier and a heating mat. I also added a digital Extech 445715 Hygro-Thermometer for easy monitoring of internal temperature and humidity. The controller I picked was the analog C.A.P AIR-2 temperature/humidity controller, which controlled temperature and a de-humidifier.

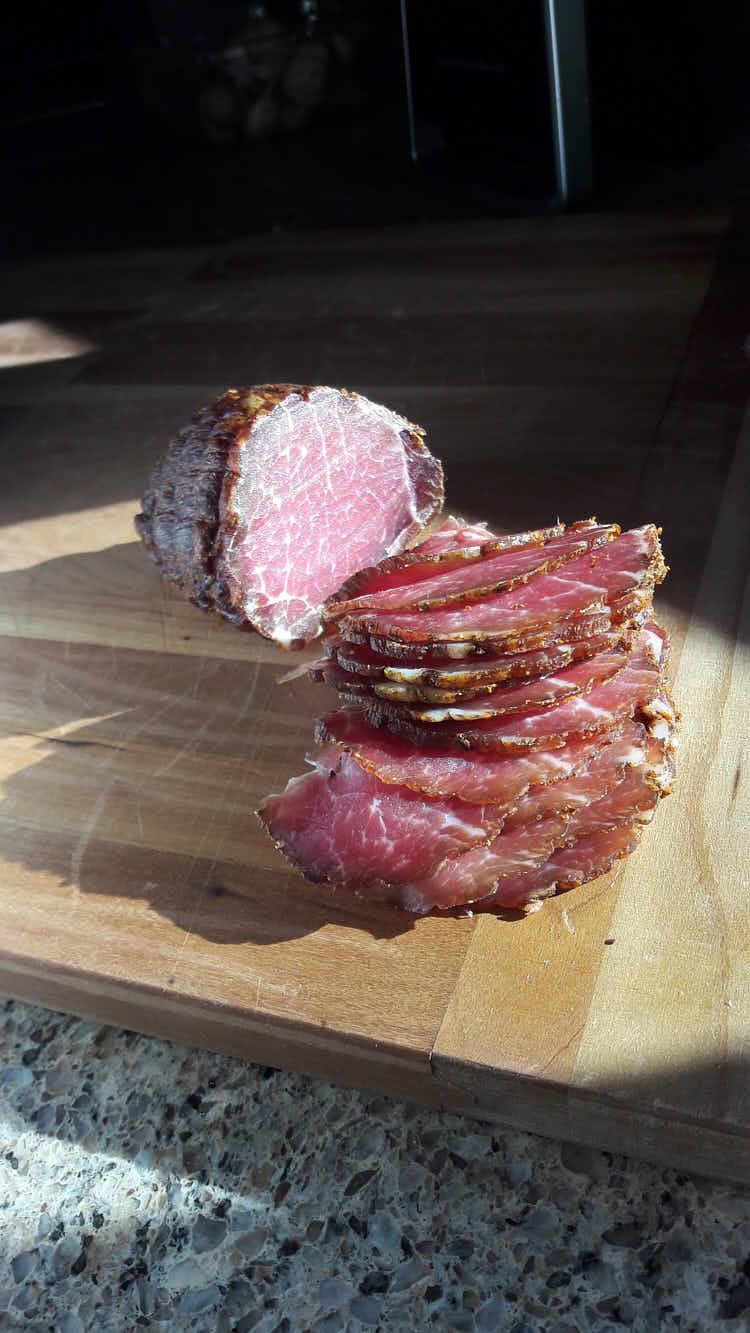

My first batch of meats turned out fantastic; I could not be happier. No store-bought salami would come even close. Michael Ruhlman's sopressata was the star.

My meat curing chamber challenges

The next batch I made a few months later didn't fare so well. My salamis would keep developing some sticky grey coating on them, which impacted drying and resulted in spoilage. Wiping off that sticky mess with water and vinegar solution would only work for a couple of days. Then it was back again. I figured I must have done something wrong and made another batch. It turned out not too bad, but not nearly as good as the first one.

Then I realized what the problem was. It was the changes in the ambient humidity that affected the humidity inside the meat curing chamber. When the ambient humidity was suitable, the internal humidity in the fridge stayed in the desired range, and I would get perfect results. If not, I would get junk.

Around that time, my very old fridge died, and I was able to replace it with a practically new one that I picked up for $110 on Craigslist. Below is a picture of my second curing chamber.

The same problems continued, and I was pulling my hair out, figuring out how to bring humidity under control. Specifically, I needed to be able to bring the humidity down. Low humidity was not a problem, as I could use a humidifier to take care of that.

Solutions that did not work

The Internet is full of information and misinformation. Sometimes, the information is correct but does not necessarily apply to your conditions. As a result, you take someone's advice, but it does not work for you. You probably have been through that many times.

One recommendation was to control the humidity in the meat curing chamber with a tray of wet salt. It should provide a perfect 75% RH. That did not work for me at all.

Then, I made a big tray of sodium acetate, which I read about in one of Stanley Marianski's books. This method worked fine, but only for a few days. The acetate would quickly get moist, and I would need to dehydrate it in the oven. It proved to be too much hassle.

I now understand that these methods work well when you have relatively low humidity. When the humidity is high, these methods are ineffective. You'll never know for sure unless you try yourself.

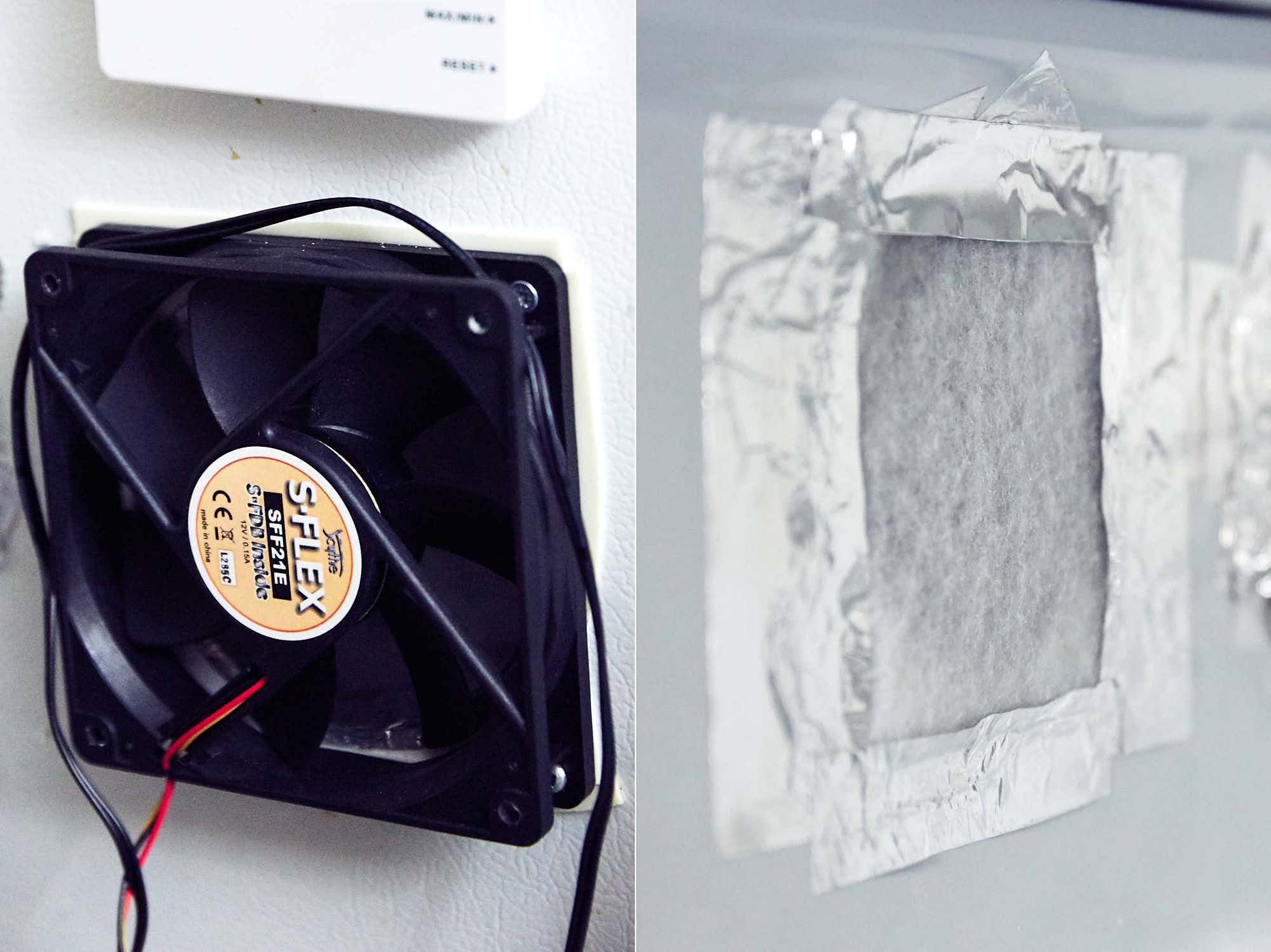

Later, I stumbled upon Marianski's recommendation to use an exhaust fan to get humidity out of the fridge. There are two ways to implement this solution.

- Set up the humidity controller to run the fan when humidity rises above a certain threshold.

- Add a timer to activate the fan at a predetermined time.

I cut two 4" holes in my new fridge, one at the bottom to take air in and one at the top to get the humid air out.

This worked for a short period of time. The humidity would still be fairly high when I would add new sausages but would come down a few days later. Unfortunately, two months later, this system started to struggle. Humidity would not get below 85%, and the fan would be running almost all of the time. A couple of weeks later, I noticed that when the fan would start running, the humidity in the meat curing chamber would increase. What the heck?

During that time, the ambient temperature got noticeably higher. When warmer air with the same or higher relative humidity is introduced into the cooler fridge, it causes internal RH to increase. That's precisely what happened to me. So, this solution works when the ambient temperature is low, or the ambient RH is much lower than the one in the fridge. Otherwise, you will be getting the exact opposite effect.

Now, some have been saying that 85% RH is perfectly fine for curing meats. I can tell you that it's not what my experience has been. Sticky goo and nasty molds would attack my meats at high RH. I also noticed quite a bit of case hardening. That was surprising as you are more likely to get case hardening at low RH.

I kept looking for other methods. Some are using ceramic heater lamps, which are discussed here. This method can be dangerous and, frankly, does not make much sense to me. Why would you want to heat the fridge to make it circulate more often? I also noticed that as soon as the fridge stopped running, the RH would shoot back up within 20 seconds. Somehow, the moisture needs to be removed. That seemed like a more practical solution for lowering RH inside the curing chamber.

The solution that worked

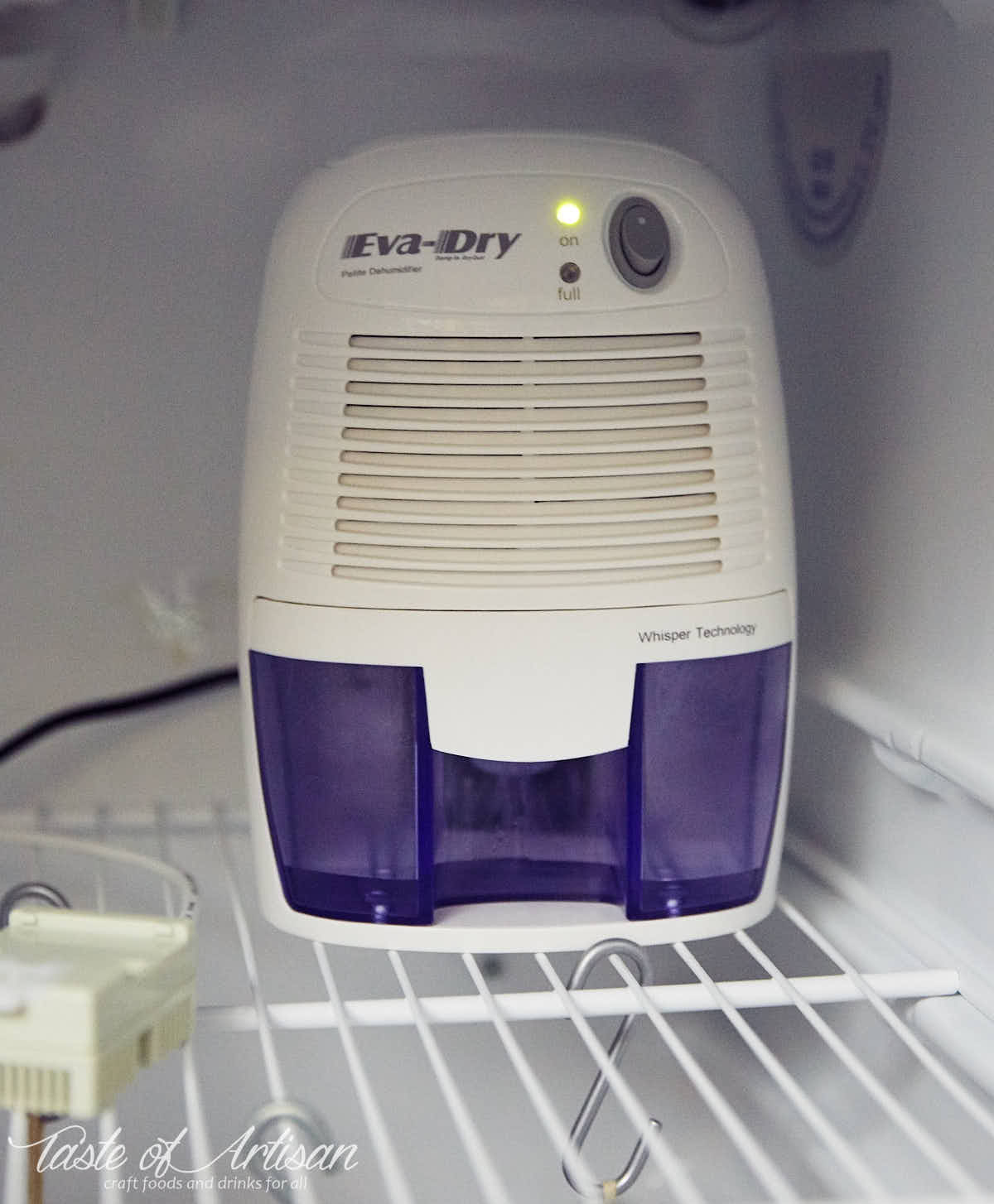

This all led me to look into installing a dehumidifier in the meat curing chamber. I thought that maybe that would be the solution. Any small-size dehumidifiers I was able to find were using Peltier technology. I've seen numerous posts on various forums stating that these types of dehumidifiers don't work at curing chamber temperatures. Darn!

Luckily, one person on Reddit forums reported using one of these dehumidifiers with great results. I took the plunge and bought the Eva-dry Edv-1100 Dehumidifier, and I am glad I did. It worked, and it worked exceptionally well. It's still going strong after ten years of use, by the way.

This is a smaller version of the one that the poster from Reddit had, but it worked just as well, from my experience. Another benefit of the dehumidifier was that it provided some air movement when it was on.

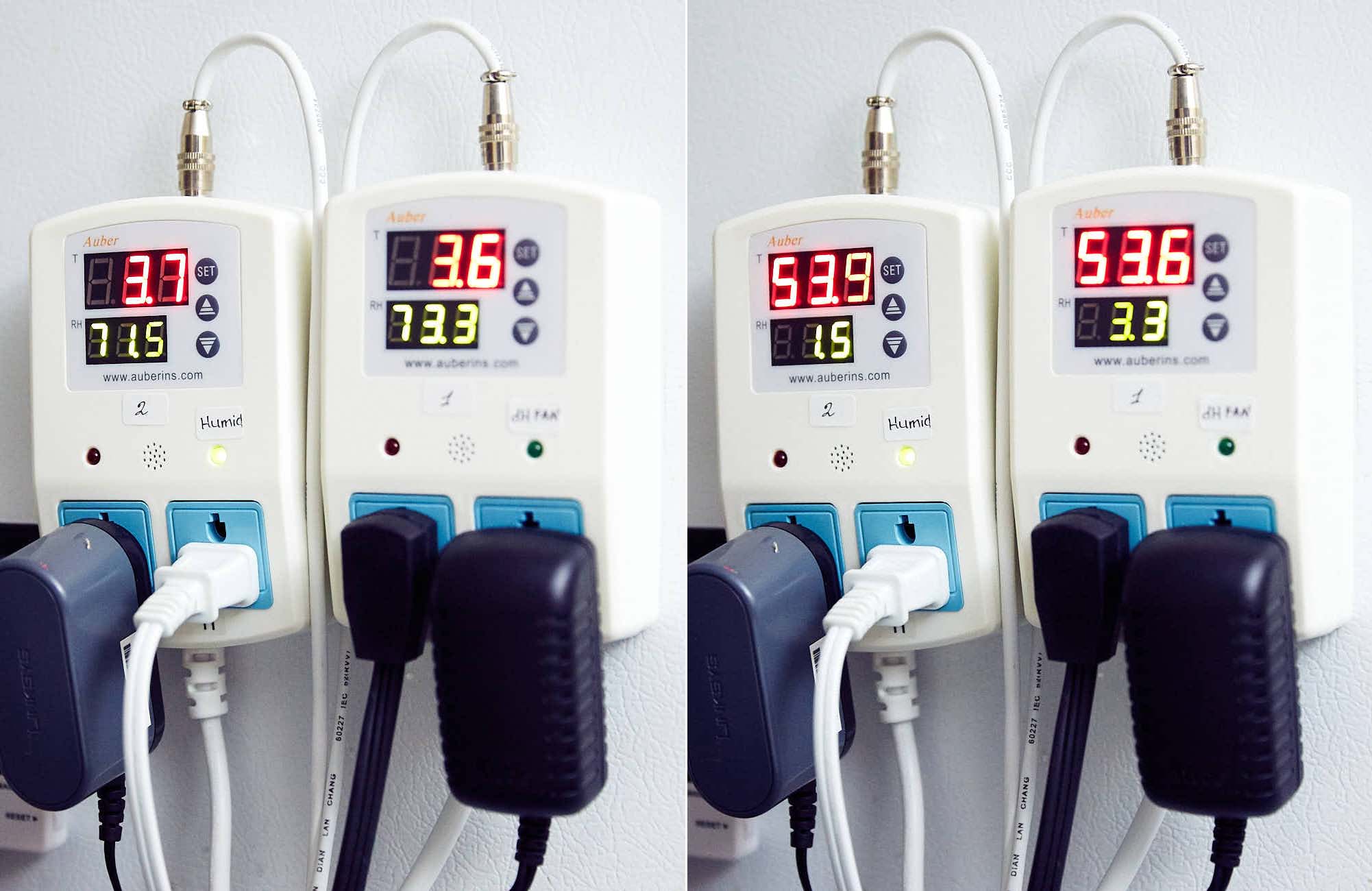

I replaced my less-than-stellar analog controller with the Auber TH210 Temperature and Humidity Controller for more precise temperature control.

This controller also controlled the Optimus Cool Mist Ultrasonic Humidifier in my setup. Later, I added another one to control the Eva-dry Edv-1100 Dehumidifier. I also had an exhaust fan plugged in, but I quickly stopped using it as I realized I didn't need it. I took two pictures as the numbers on the controller flickered when I took the shot.

There were slight differences in the temperatures and RH reported between the two. I think it was the result of sensor placement and air movement. I could especially notice the difference when the fridge was circulating and cold air was blowing inside the fridge. When there was no air movement inside the fridge, they had almost identical readings.

The way this setup worked was one controller was set up to start the humidifier when RH dropped below 72%. Because of a slight lag, the RH drops to about 70% before the humidifier is able to start bringing it back up. Still, this was sufficiently fast.

You may have noticed that I moved the humidifier outside the fridge in the new setup. The reason behind this was that it was easier to control humidity in larger spaces. The humidifier was pretty bulky and took up a lot of space, so it made sense to move it out.

The other controller controlled the dehumidifier and kicked in when the humidity went above 78%. Again, due to a lag, the RH briefly would go up to about 80-81% before it was brought back down below 78%. The average was about 75% RH, which is precisely where I want it to be. I could tighten the range down to a 1/10th of a degree, but that was not necessary. I didn't want the humidifier and dehumidifier to start competing with each other in a vicious cycle.

Like I said, I felt like I was in charcuterie heaven.

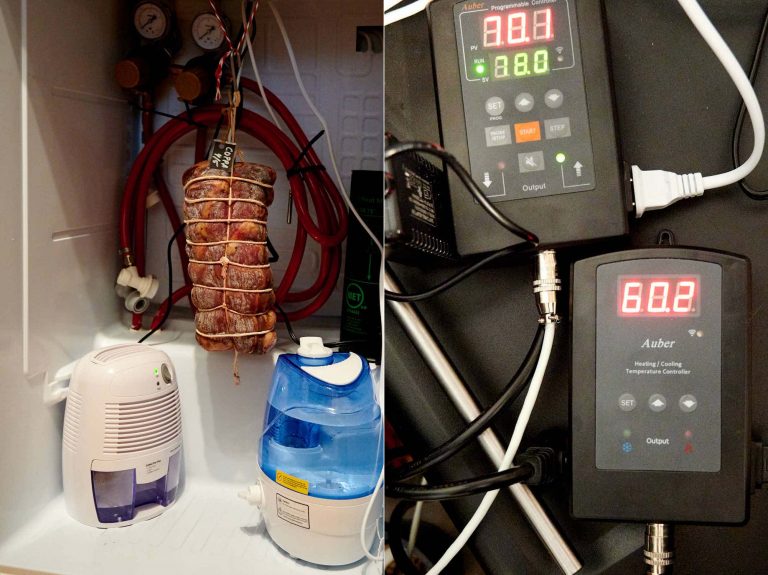

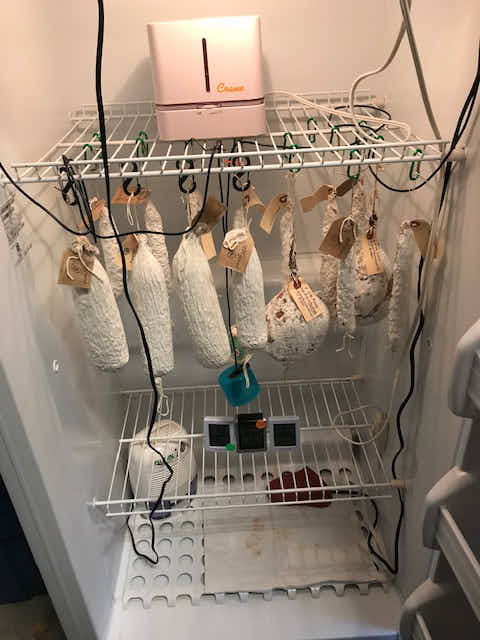

Fast forward to today. I've learned a lot over the years. Charcuterie is my passion, and I still make cured meats on a very regular basis. My curing chamber looks quite different from what it looked ten years ago, but the idea is pretty much the same. Even the dehumidifier is still the same.

My updated curing chamber setup (as of 2023)

One of the most asked questions I've been getting over the past couple of years is what my current curing chamber looks like. I apologize for the delay; I should have done this well over a year ago. You know how it is; things constantly get in the way. I also had some challenges running electrical wiring to where I needed it. My setup is still evolving, but I've come to realize that it is a part of this hobby. I will constantly be modifying and improving it. For now, here it is, with all the details that will help you build your own fantastic curing chamber. I think I am 97% there.

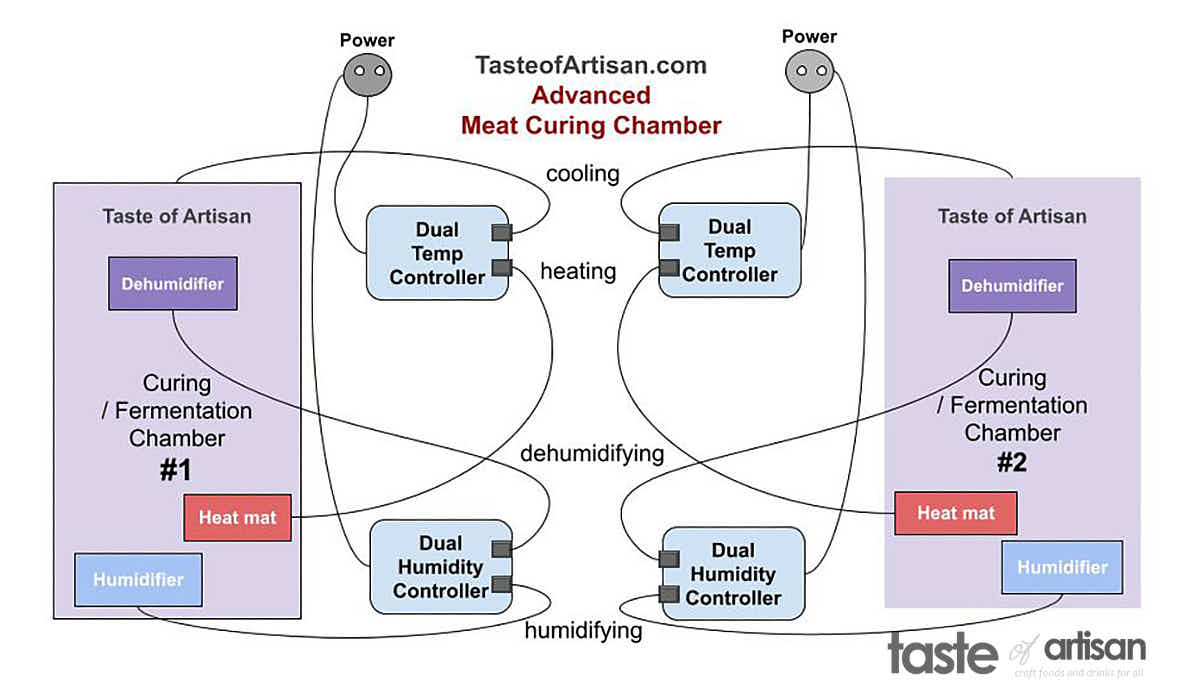

The architecture of my new meat curing chamber setup

If you do a good amount of meat curing at home, you've no doubt run into a problem where you need to do fermentation/drying for a new batch while your curing chamber is occupied. I've had this happen to me so many times that I got really tired of it. And I got tired of fermenting my meats in make-shift fermentation 'chambers,' such as coolers, bathrooms, in front of a fireplace, etc. They kind of work but not very reliably and have limitations. Besides, seeing sausage hanging in your bathroom is odd, to say the least.

So, I decided that a dual-chamber setup was what I needed. I was not wrong. I am truly in heaven now. With this setup, I can ferment new batches at their own pace, temperature, and humidity in one chamber while older batches are maturing in the other chamber, undisturbed.

Another thing that is cool about the new architecture is that it's multipurpose. I can use one of both fridges as a curing chamber, fermentation chamber, or plain fridge. My wife is particularly happy about that. There are no holes in the walls of the fridges, and the switch-over literally takes less than half an hour.

Below is the diagram of how all the curing chamber components interconnect with each other, something some of you have asked me to do.

The fridges

I had a hard requirement to make the new meat curing setup look nice. That meant that I needed identical fridges. My other hard requirement was to use only freezer-less fridges. Over the many years of curing meats, I've learned that more space inside a curing chamber means better and easier humidity control and more space for meat. I settled on LG LRONC1404V fridges, which are freezer-less, spacious, and have been doing a great job as curing chambers.

Humidity & temperature controllers

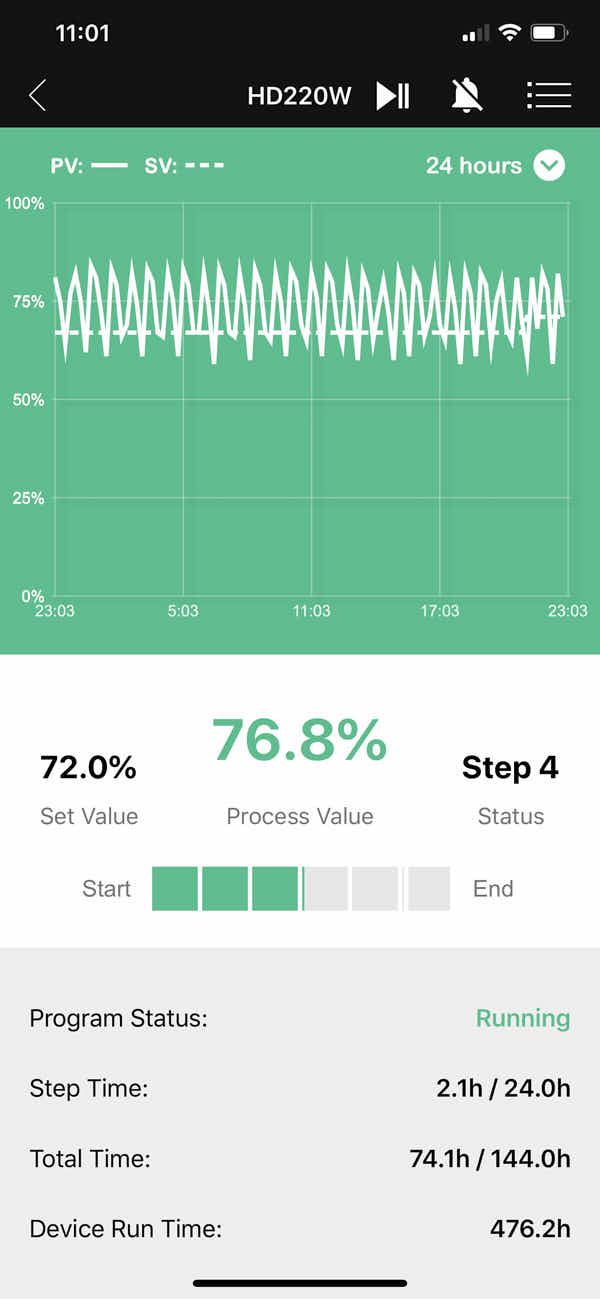

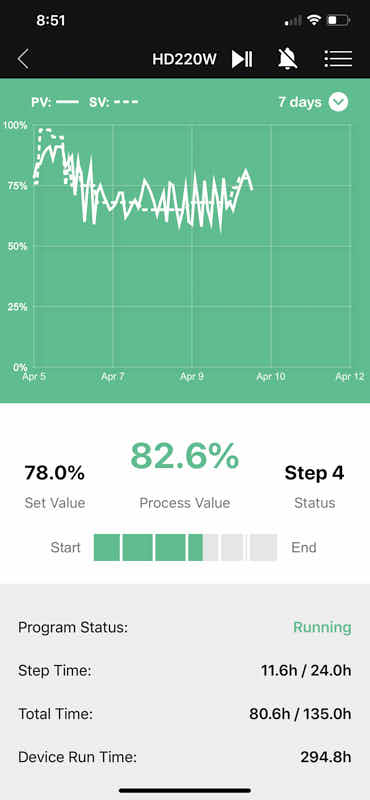

I am still using Auber Instruments temperature and humidity controllers. The fridge on the right in the picture above uses the newer AW-HD330 (humidity) and AW-TD130 (temperature) wireless controllers, while the fridge on the left uses the older model HD220-W (humidity) and TD120-W (temperature) wireless controllers.

The controllers are attached to the sides of the fridges using 3M VHB Tape 4910 1" double-sided tape, which holds them very securely. Also, these Auber controllers have very short power cords, so I had to add 6' heavy-duty 15-amp extension cords.

Additional thoughts on controllers

I thought I'd elaborate a little on controllers. The most obvious and popular choices are Auber Instruments and InkBird (Humidity Controller IHC-200-WIFI and Temperature Controller ITC-308-WIFI). Both are popular, WiFi-enabled, feature-rich, and both do the job.

Back in 2020, I tested both brands, see my Best Controllers for a Meat Curing Chamber post, and found that, at that time, Auber controllers seemed to be optimized for the curing temperatures of around 55F, while Inkbird seemed to be more accurate at higher temps and vice versa. Both Auber and Inkbird humidity controllers were not perfect and need to be calibrated. The deviations that they showed were significant enough to have a noticeable impact on curing results.

If you calibrate them at 55F, will they still be accurate at 70F-80F during fermentation? This is where a reference hygrometer like Hanna HI9565, discussed below, becomes useful.

Dehumidifiers

I've been using Eva-Dry peltier dehumidifiers for the past eight years or so, and they proved to be working well, without breaking, and doing exactly what they are supposed to. I started with one and added another dehumidifier later as I needed it for my make-shift fermentation chambers. Now, it sits in the new curing/fermentation fridge when needed. These dehumidifiers, the specific model and look, haven't been sold under the Eva-Dry brand for many years, but you can buy them under different names/brands. It's the same dehumidifier. Eva-Dry now has new restyled models, EDV-1200 (similar size to mine) and a twice as large EDV 2500, but I have not tested them yet.

Humidifiers

Of all the parts in my meat curing chamber setup, a humidifier has been the least important one. I can cure anything without a humidifier. In fact, I've been doing exactly that for the past two years or so. Meat constantly releases water during the fermentation, drying, and maturing phases. There is plenty of humidity in the curing chamber at any given time except for a brief time when the fridge cycles, after which it quickly recovers.

In my setup, the only time I want to add humidity is when the meat is quite dry and doesn't release water. That's when I turn on the humidifier. The humidifier that I bought in 2013, 10 years ago, and am still using, is the Optimus U-31001 1.5-Gallon Cool Mist Ultrasonic Humidifier.

Alternatively, I simply place a tray of water to provide a little bit of humidity, and it works reasonably well for me.

Heater

Since I use my new curing fridge(s) for fermentation, I need a reliable but safe source of heat. After testing a number of heat sources over the years, I've come to really like 10"x 20.75" seedling heat mats. These work exceptionally well in my fridges, and I feel safe using them as they don't get hot and are reasonably waterproof. I have several of them. Every time I buy them, they seem to be sold under a different brand name, but they are exactly the same.

Reference Hygrometer

This piece of equipment is optional but very useful if you want to keep your temperature and humidity controllers perfectly calibrated and accurate. It's Hanna Instruments reference Thermohygrometer HI9565, shown on the right in the picture below, next to my old Auber controllers. I've been using it for many years, and I find it quite useful as I like precision.

Airflow and ventilation

Since I am not making any holes in my fridge, the question is, what about airflow, letting fresh air in, etc.? Airflow is important. In my old curing fridges, I had exhaust fans and an internal fan to blow the air around. Quickly, I realized that it caused more harm than good. My results have been much better without them. The dehumidifier turns on frequently, especially during the initial stages, and provides enough air circulation from its built-in fan. Additionally, when a fridge circulates, it brings in ambient air (which is cooled down first) and pushes out some of the stale air from the fridge. I find that this is sufficient to make excellent cured meat.

Helpful Relevant Resources

Green Mold on Salami - Good or Bad?

Barney says

Success!

G’day Victor,

I think we figured it out. It was the original InkBird (IB) hygrometer that was the issue as the other two hygrometers I used, whilst having small variations between them, they were both significantly lower than the original through. Over the last couple of weeks they averaged readings of around 70-78%, whereas the IB was a good 10-15% higher.

I pulled the salamis out on the weekend, and for a first attempt, I’m pretty bloody happy with them. I’ll try to attach a couple of photos on here. I had them spread over three levels in the fridge, and with my setup I found the highest shelf, closest to the de-humidifiers, they lost between 43-45%, the middle level lost 37-39%, and the two single salamis at the very bottom lost 48%. Not sure if that’s because there were only two of them on that shelf, or because they were closest to where the fridge air comes in. Given the temps in there it was rare for the fridge compressor to kick in. I kind of don’t mind how it worked out as it allows us to try them at those different stages of drying so we’ll be able to figure out which we like most.

I have one last question here. If using natural casings, as I have this time, do you need to skin them before vac packing them, or could I have just wiped them down with a water-vinegar solution, or wine as some recommend?

Notice I said “last question here”, that’s because I’ve got a few more based on other recipes you have on here that I’m attempting next. I’m tacking the pancetta, capicola, and two big salamis next. I was thinking the Tuscan and Calabrese.

Thanks again for your direct advice, as well as the advice and instructions on the website. It’s top notch.

Cheers,

Barney

Victor @ Taste of Artisan says

Hi Barney, glad to hear about your success! I am not surprised, these relatively cheap hygrometers can be unreliable. I tested many of them and not a single one has been bullet proof. My Hanna reference hygrometer is probably the only one that's reliable, but sometimes I feel that it may be a few degrees off at certain temp/humidity levels. Once you do more batches, you will learn to 'feel' the correct humidity. Make a lot of observations and take a lot of notes initially. Correct humidity is when the skin is just slightly moist, not wet and and not dry. It's not hard to see. Then adjust your controller to increase or decrease the humidity accordingly.

Variation in weight loss in different parts of the fridge probably indicates humidity variability in the fridge. Humidity rises, so it's natural to see my drying at the bottom of the fridge and less at the top. A stronger air flow can fix that. Also, rotating the meats.

You can vac seal with a or without the casings. If they have a lot of mold that got grey and unsightly, you can wash it off, dry and vas seal. Or you can remove the casings and seal without them. I've done both ways. I think I prefer without the casings, as I batch process all of them once and not have to deal with them later over and over again. If it goes in the fridge, unsealed, I always keep the casing on to slow down drying. I just wash the mold off, soak in a little bit of wine, dry with paper towels and refrigerate.

Hope this helps. Apologies of the delay responding, I missed your message in the pile of spam.

Best,

Victor

Barney says

G’day Victor,

How long should it take for the humidity to get down below 80%? I’ve made a 12kg (26.5lbs) batch of salami on Saturday and put it into a curing chamber built as closely to yours as I could. I’ve got two of those same (looking) dehumidifiers in a large drinks fridge, but I can’t get the humidity below about 90%. Today is their fifth day in the chamber.

When the fridge kicks in it drops to around 72%, but the temperature in the garage is only around 12.5 degrees C (54.5f) so it rarely has to.

Thanks for your help.

Cheers

(I sent a much more detailed initial message, but it didn’t post).

Victor @ Taste of Artisan says

Hi Barney, I got your previous comment and responded to it. They don't post automatically as I have to approve them manually. Too much spam gets in the queue. Sometimes I don't see legit messages right away as they get buried in the spam. But I do my best to go through all of them and make sure I don't miss any.

Barney says

G’day Victor,

Thank you for your response. I hadn’t noticed the little message about waiting to review the comment until the last shorter version, so I thought perhaps there was a character limit. Thanks again, I’ll respond to your answer to my question below.

Cheers,

Barney

Victor @ Taste of Artisan says

No worries, Barney. Hope we can figure this thing out for you.

Barney says

G’day Victor,

Firstly, thank you for combining your knowledge and experience and making it available on this platform for newcomers like myself. It’s the clearest, most in-depth resource I know of on the internet, and it’s a credit to you.

I’m very new to this and have a question for you regarding the humidity of the chamber.

I was invited to a families salami making day (my first), and in preparation of that I built a curing chamber, as closely to your latest build as I could. The people I made it with just hang theirs in the sheds/garages, but that’s not an option for me.

All went well through the fermentation stage with temperatures staying close to 22C (71.6f) and humidity at 97% plus for those 48hrs or so, but since moving into the drying/maturing stage with the temp set to about 13C (55.4f) and humidity to 75%, I have not been able to get the humidity below about 90% for most of the time, despite having two de-humidifiers that look the same as those you use in the chamber. When the fridge kicks in it will reduce to around 72%, but it quickly rebounds when it stops. The fridge kicks in infrequently because the temp in my garage is only getting to about 12.5C (54.5f) max. at the moment.

I’m trying to tell my rational self that I’ve just put about 12kg (26.5lbs) of wet salami into the fridge and it’s going to take some time to dry out, but being very new to this I’m also mindful that I don’t want humidity above about 80% as per most instructions I’ve found. I’m like a bloody nervous parent watching over them like babies at the moment. They’ve been in the chamber just over four days now.

What I’m wondering is, is this all very normal and I should just let it go and the humidity will eventually drop as they dry out, or should I try to do something to drop the humidity, and if so, what? I could drop the temp threshold setting down so that the fridge cycles more often, but is that necessary?

Thank you for your help, I’d be happy to read whatever recommendations you can make.

Cheers

Victor @ Taste of Artisan says

Hi Barney, thank you for the kind words and welcome to this new and exciting hobby.

Humidity not dropping can be caused by two things: 1 - too much meat, which loses a lot of water in the first week. 2 - your dehumidifiers either aren't powerful/efficient enough to extract all that humidity, or they don't work properly. Another underlying cause can be the fridge itself. Is it frost-free? I assume so based on what you said. If not, that makes it much harder to control humidity. Is it large or small? A small, 5-11 CF, fridge will be much harder to control humidity in, while a large 15-25CF fridge will be much easier.

The frequency of circulation can be good and bad. Good as it helps bring the humidity down. But the more often the fridge circulates, the most risk for case hardening, depending on where the cold air blows.

I often tell those who are new to this hobby to expect to tweak their setups initially. If you replicate my setup perfectly, there is no guarantee that it will work just as mine as your environment will be different, and that makes a difference. Hence, it's a good idea to start with a small batch, observe, make notes, tweaks, then increase your batches as you go.

But, we are where we are, so how do you deal with that? Well, if I were in your shoes, I'd probably keep the door of the fridge cracked open for a week or two to bring the humidity down. Is that possible? If so, that's a great solution as the ambient temps are where you want them to be. I assume the humidity in the garage is lower than 80%. Once the meat loses most of its water, you can close the fridge and it should be much easier to control the humidity.

Now, in parallel, try to figure out why your humidity doesn't drop. I normally have no issues with that and my batches are around 18-20 lbs I would say. It varies though. Do you see a lot of water collected in the tanks? You should see at least half a cup per day to a cup at those levels of humidity. If not, maybe consider replacing them.

I would definitely try a smaller batch next time to give yourself more room for dealing with various quirks any new system will have. Once you have figured it out and make it work, increase your batches and see how your system behaves. Hope this helps. Let me know if you have more questions and good luck!

Barney says

G’day Victor,

Thanks again for getting back to me. Curing meats at home is something I’ve wanted to do for years. You’re right, I probably should’ve started with a significantly smaller batch, but the people I was doing it with had bags of minced pork ranging from about 11-15kgs (24-33lbs) there, so I just grabbed one and went with it.

The fridge is a large single door frost-free drinks fridge, with internal dimensions approx. 1420mm high, 620mm wide, and 550mm deep. The two dehumidifiers both have about 40-50mm of water in their collection tanks right now. I’ll probably empty them tomorrow.

For the last couple days I have been leaving the fridge door ajar through the day, but I have to close it overnight as the dog goes in there. Most days it has helped to drop the humidity down to around 76-78% when the door is open. It is a bit more humid than normal at the moment as we’ve had a fair bit of rain. When the door closes though it’s up again at 90+%.

I may have hopefully found the solution. Today I got a second small thermometer/hygrometer and put the sensor next to the InkBird sensor and right now it’s reading 77% while the InkBird is reading 86%. I’ll be interested to see what happens when I close the door up. I’ll buy another separate hygrometer and put that in to see what it has to say. Hopefully it’s closer to the new one than the InkBird. Temperatures are almost identical across both.

The InkBird was unused, but I have had it for a couple of years. Like I mentioned, I’ve wanted to do this for a long time but haven’t had it opportunity until now.

I’ll keep you posted. Hopefully I’ve been worried about nothing all this time and the humidity was always okay. They look pretty good with a decent covering of bright white mould, with no greys or greens. Let’s see how we go.

Thank you again, Victor. You’re going above and beyond to help people like me, and it is appreciated.

Cheers,

Barney

Victor @ Taste of Artisan says

Glad to hear it, Barney. Looks like you are on the right track. I hope your first batch is a success. I totally get why you went with a large batch as you first very adventure into it. It's hard not to. I remember my first batch. I geez. It was a mix of many things as I wanted to try everything right away LOL

Ah, I should have thought about your hygrometer. Yes, they can be quite unreliable sometimes. At one point I got me a Hanna reference hygromter to test all of my controllers and other hygrometers and I saw some big deviations. That said, I rarely rely on humidity readings alone anymore. Let's say I want humidity to be 75%. I set my controller to 75% but I also monitor the surface of the sausage. I want it to be hydrated, but not wet. I also don't want it to be dry. If it's dry, I bump up the humidity. If it's wet/sticky/slimy, I drop the humidity. That's the best way IMHO.

Anyway, good luck and keep me posted. I'd love to see some pictures too.

Dave Nussbaumer says

Great job, quick question. In your opinion will a Pepsi cooler in great working condition work?

Victor @ Taste of Artisan says

Dave, I've seen people use just about anything. The question is how well it will work and how big of batches you can cure. You best bet is to use a frost-free refrigeration unit. The second most important thing is to use a large unit. They larger it is, the easier it will be to manage humidity. In small units, humidity may be too difficult to manage. It also depends on the amount of meat in the fridge. The smaller the fridge, the less meat you'd want to put in it to be able to effectively manage the humidity. I wish I could give you a simple answer, but it's impossible. Too many factors to consider and deal with.

Joe says

Hello, I've been curing meats for over 4 years now and one trouble I keep on getting is that my freezer (controlled by my controllers) dies , time after time, evaporator got holes in them (as per the technician) even after being replaced twice, and wondered maybe if the humidity (80%) is causing that for any of you.. or heard of it

Victor @ Taste of Artisan says

Hi Joe, sorry to hear about your troubles. So far, I only had one fridge die on me and it was a very old fridge. One day, it just stopped working. There was no point in repairing it so I replaced it with another, newer fridge I found in local classifieds. My other fridges, including the brand new ones, did not have any issues. Knock on wood.

I am not a fridge technician by any means and know very little about the mechanics and how to fix them, etc. But a couple of things immediately come to mind, so I will share them, perhaps that will help. One is that your unit may be faulty and just needs replacing. Dah.. LOL Anyway. The second is... you said it was a freezer. I am not sure how suitable freezers are for this task. Aren't they designed for sub zero temps? Perhaps running them temps well above freezing temps may be the problem. Also, is it frost-free? Non-frost free units aren't well-suited for curing as maintaining proper humidity levels is a huge challenge with them, as I've learned from my own experience.

John says

What a great resource. Thank you for putting all this together. I'm looking forward to building my first curing chamber and learning to cure my own meats

Victor @ Taste of Artisan says

You are welcome, John. It's a very rewarding hobby that doesn't seem to get old. I've been curing meats and sausages for well over a decade and I still do it and love doing it. Good luck!

Julia says

How do you use the heat mat? Do you turn your fridge off temporarily to raise the temp, or do you let it compete with the mat?

Victor @ Taste of Artisan says

No, the fridge and the heat mat are both plugged into the temp controller simultaneously. I don't want them to compete. The set points for heat and cooling are 3 degrees apart (68F for cooling and 65F for heating) with a 1 degree differential for cooling 2 degrees for heating, which ensures that they stay out of each other's way.

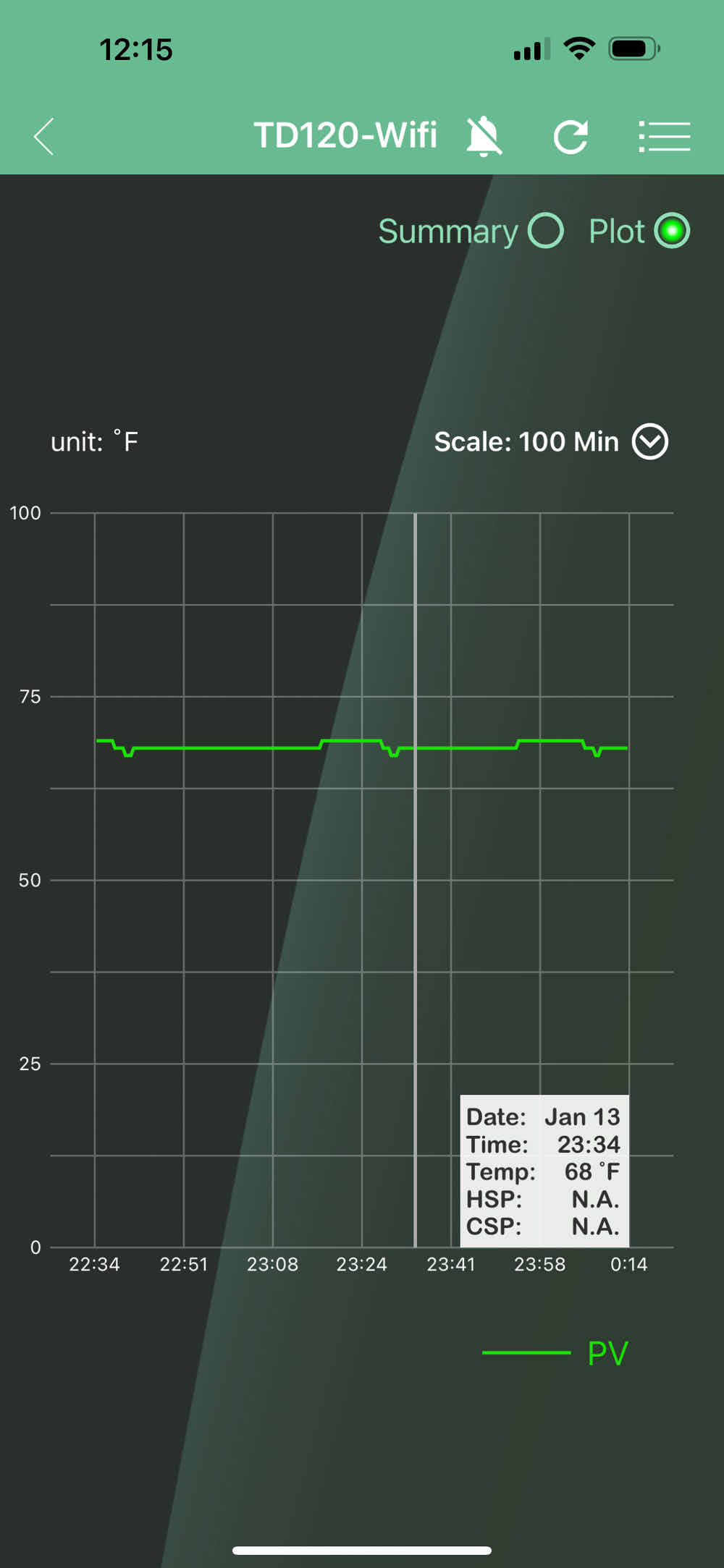

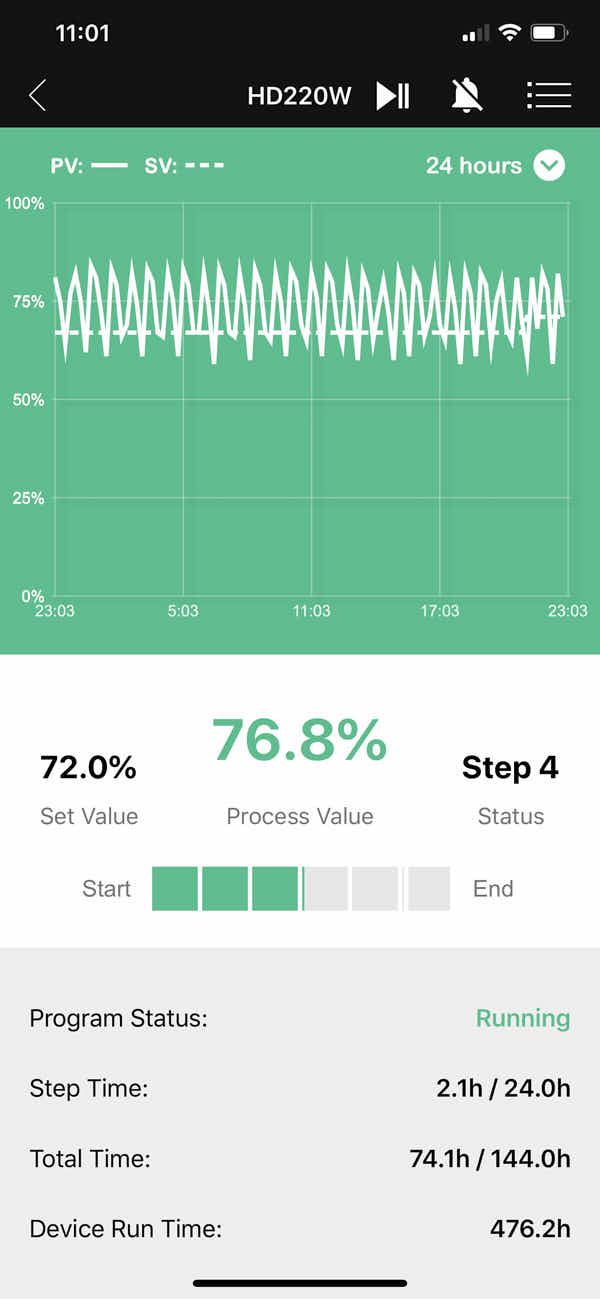

I am fermenting a batch of salami right now, needing to keep the temp at 68F for a certain period. Here is what temp plot at those settings looks like:

M says

Hi,

how many mm is the outer and inner diameter of the tube that you used for the humidifier? i connected a 8/6mm tube to my humidifier but condensation gets stuck and it stops working after a minute or two?

Thank you.

Victor @ Taste of Artisan says

5/16" ID x 7/16" OD or 8mm ID x 11mm OD

M says

Thank you ordered one of those now. I also have a issue with my curing fridge (frost free). The humidity near the back wall of the fridge is higher and causes drying issues. Do you face this problem as well? If you don't mind can you please also share clear pictures of the humidifier tube entering the fridge and the location of it in the fridge? Thank you.

Victor @ Taste of Artisan says

I got rid of my older fridge some time ago an only use my two LG fridges as my curing chambers. Neither has any holes in it. Since these new fridges are freezerless and quite tall, I keep the humidifier inside. Also worth pointing out, I really only use the humidifier toward the very end of the maturing period, then the meat and sausages are dry and don't release much water into the air. Until then, I only use my dehumidifier. I seem to have plenty of humidity in my chambers so I don't need to add any more.

If you have issues with humidity in some part of the fridge, it means you need to improve internal air circulation. Install a small fan. I used to use a fan but now it seem that my dehumidifier's fan does a pretty good job. Also, it may not be humidity in the back causing case drying issues... Do you mean the casings don't dry in the back? Or do they dry faster and harden? If the latter, you may have cold air blowing there when the fridge circulates. YOu can shield that area or re-arrange the meat. Hope this helps.

Chris D says

I set up a curing chamber with your equipment suggestions. I am using the Aubur AW-HD330 for humidity control. I have my humidity set at 80%. The controller is calling for the Eva-Dry EDV 1200 to come on as the chamber humity climbs above 90%, but the dihumidifer won't turn on without me manual pressing the on/off button. I have tried taping the button in the depressed position when the machine is on, but when the controller shuts it off and then calls for it to come back on it won't start unless I uncover the button to release it and press it on again. Is there a trick to get the Eva-Dry to come back on with the Aubur turning it on and off?

Thanks

Victor @ Taste of Artisan says

Hm... that's puzzling... I have three Eva Dry or similar to Eva Dry (same design, different brand) dehumidifiers and none of those behaves the way you described. I don't know, maybe the newer designs need to be manually activated. I don't have a solution for your problem as I never had to deal with it, but if you purchased yours on Amazon, Id return and replace with a different model.

rebecca says

Sweet Setup! Do you have any suggestions for dealing with mites in your cave? I've got a case of mites on some of my older whole muscle cures (6 months old) Ive treated them with wine and dry brushing.... any suggestions for how to treat mites? also deep cleaned the curing cave with vinegar. Thanks in advance!

Victor @ Taste of Artisan says

Apologies for the delay responding to your comment. I had no idea you could get mites on cured meats. I've only seen them on my plants, which I treat with sulfur/castile soap, but I wouldn't use that on cured meats. If you google for 'mites on cured meat', you will see many resources pop up with recommendations for how to control them/get rid of them. Good luck!

Mathieu Caron says

Hi, thanks for all those information, im wondering if an electric wine fridge/cooler would be simplier than building from a fridge? since on some model you can choise the desired humidity %

Victor @ Taste of Artisan says

Hi, the biggest challenge for me was controlling humidity. I found that the large the space the easier it was to control humidity. Frost free fridges are much easier to control humidity in. Once you start loading a small fridge with meat, humidity shoots up and becomes harder to control. So, my recommendation is a frost free fridge with as much volume as possible. That said, if you can find a small wine ridge with humidity control, and you don't anticipate large batches, it should work. Good luck!

Leo says

Great article. Why are you using a heating mat in the refrigerator? I only guessing that it's to prevent the temperature from continuing to drop after the refrigerator reaches the set low temperature threshold?

Victor @ Taste of Artisan says

No, I use a heating mat for fermentation and initial drying when temps need to be above the ambient temps.

Mike says

Thanks for sharing your experiences… It is very useful. I am in the process of putting together a curing chamber, using a wine cooler. I have decided to introduced humidity from the outside to save space. What do you think would be the best location to introduce the humidity into the chamber. What I mean is high or low or front or back?

Thanks again for all the helpful information. Mike.

Victor @ Taste of Artisan says

Welcome to the hobby, Mike. Your question requires a lot more background info that you gave me to give you a proper answer. How big is your wine cooler? Frost free? Frost free are best, non-frost free ones will be hard to control humidity, smaller ones will be next to impossible. Adding humidity to a small non-frost-free fridge sounds like a really bad idea to me. I rarely use a humidifier with my frost-free fridges. The biggest challenge is to remove humidity, so I'd be concerned with getting a good dehumidifier first. That said, I'd get an accurate hygrometer and test your fridge first and go from there. Different devices may act very differently so there is no universal answer. The best way is to test and tweak. Hope this helps.

Mike says

Thanks for the quick response Victor… I have a small wine cooler 6 ft.³ I believe. It is frost free. I did hang some strings in it and it does not appear to be blowing around a ton of air. I live in a smaller condo, so I don’t have room for anything much larger.

My first thought was like yours that I would not probably need to add humidity, but the more I read the more it seems like that would be necessary. but I now think those people were talking more about larger set ups than mine. I did buy a small dehumidifier that fits nicely inside the space.

I have a thermometer – hydrometer connected via Bluetooth and when the temperature ranges between 62.5 and 64.5 the Rh goes from about 40% up to as high as 85%. Obviously in the opposite direction of the temperature. And this is with no product inside and the dehumidifier not running and not hooked up to its controller.….just a trial run. I am dropping that temperature down to see if I can get it to sit in the 55° range or so… I do have a controller for the Refridge as well, but may not have to use it unless I want to use the alarm function.

We are at this time in a pretty hot/humid slice Of ambient temperatures right now.

I guess, as you suggest, I’ll go without humidification at this time, and just tinker with it to see what works and what doesn’t. That’s part of the fun of it I guess.

I am planning to cut my teeth on some kind of whole muscle cure… Perhaps Bresaola? Any recommendations? Or any thoughts on my above comments?

Thanks again…

Mike

PS. Any tips as to where to locate my temperature and humidity probes?

Victor @ Taste of Artisan says

Sounds like a good plan. Observe how your setup behaves and tweak it, that's the best way. When you add wet meat/sausage, it will be a different story. Especially a sizeable amount. I don't need to run a humidifier until almost when the sausage is done maturing. Until then, whatever is being released by the meat is enough. Of course, that's very setup and ambient environment specific. In dry areas, that probably will be different. If the fridge is not well insulated and need to to circulate frequently, that will keep the RH very low. If the ambient is low, the fridge won't circulate as often, when high, it will and the RH will be kept low, so in those scenarios you will need a humidifier. Sizewise, the large the fridge, the easier it is to keep RH stable.

Bresaola sounds great. Lonzino or capicola are also good ones to try.

I hang my probes where my meat is/will be. Don't want to hang too low or too high.

Ken says

Hi Victor

I am trying to cure prosciutto and I started with a 21+ lb rear leg in November. I followed the instructions exactly, with salting the leg with cosher salt and putting in the refrigerator with a cutting board on top and weight to press it, day 4 removed and drained water and re-salted, back in refrigerator for a week, pull repeated last step, back in refrigerator for another week, repeat last step again, at day 21 removed and brushed off salt and rinsed with 2 to 3 cups of red wine, then wrapped it in collagen sheets. This is when I weighed it and it was 21 lbs. I then put it in my curing cabinet built with your specs and have been running it since December, started out at 80% humidity and 55 degrees, over the last 7 months I have been dropping the humidity because I cannot get it to drop the 30% weight to finish the curing process. For the past 3 months or so I have had it at 68% humidity and 55 degrees, and I am still a little over 2 lbs from hitting the 14 lbs that I need? Any suggestions I would greatly appreciate. Thanks again for such a great job on this website how to build the curing cabinet. Ken

Victor @ Taste of Artisan says

What jumps out at me is wrapping in collagen part, this is not a how prosciutto is normally made. It could have played a part. Another thing I notice is how short the salting step was. Usually, salting, reposing, and ripening/drying takes up to 12 weeks at various levels of humidity. Only after that the exposed flesh is traditionally covered with a mix of flour/fat for further maturing.

There isn't much you can do at this point other than keeping the humidity at the level where you continue dropping hydration and weight until you reach your target. Good luck!

Tim says

Actually the typical curring stage rule of thumb is 1-2 days per kilo so 10-20 days. So he was good on the cure. The issue is moet likely as you first alluded to the collegan wrap. It absolutely decreases the rate of moisture loss. Its how it works well in dry aging meats in normal frigs with no humidity air flow control. He needed as you stated to have only covered the exposed ends with the lard flour mixture. As he has done he has added an entire layer on top of the skin layer thus greatly reducing dehydration.

The question is what to do? As he has cured it for the times I have eeen listed per lb it should be throughly cured so spoilage should not an issue. Really its just doing a much slower aging at this point. My guess and I am a rank amaeture at all of this would be to do as he is and keep RH low. No matter what its goimg to lose water over the next yr + of aging.

He could pull the wrap and put on the flour lard paste which then should allow normal rate of water loss. Actually that might be the best choice. Good news is as long as it was cured and temps were not too high I doubt there is a negative effect on the meat. I would go with pulling the wrap and getting the paste on

Oliver says

Hi

I saw in the photos that you run the cables underneath the door seal of the fridge (the fridge on the left, on its right hand side).

Do you ever have any issues with the cables keeping the door seals open a little too much?

I wonder whether I should cut the seals around the cables, or try going through the walls.

Olly

Victor @ Taste of Artisan says

Hi, no, no noticeable issues so far. I spread the cables so they are not stacked. I am sure there is a bit of an air exchange but it hasn't been an issue.

Pavel says

Hello! please tell us how you do the ozonation procedure during drying and after

Victor @ Taste of Artisan says

Hi there! Ozonation treatment is a non-thermal method for disinfection of meat products. I don't do that. It's one of the cool new tools for sausage making but I don't have the need for it nor resources to implement at home.

Dallas Grgic says

Victor thank you so much for this article. You inspired me to make a curing chamber and make salami. Something I have wanted to do for years. My chamber consists of a frost free fridge with two inkbird controllers with a humidifier, dehumidifier, heat mat etc. Temp and Humidity control in my fridge works well. My first batch of salami was the traditional Italian way with 2.5% salt, ground black Pepper, fennel seeds and capsicum sauce, 8.5kg of minced pork shoulder. This was fermented at 80% humidity 20 degrees c for 2 days then turned down to 75% humidity 13 degrees c. For the drying phase. The first day the salami lost liquid and smelt sweet. I quess that is from the capsicum sauce. The second day of fermentation strong odors of egg and sulfur. I am on day 4 now and still have very strong sweet smells of egg & sulfur. The salami looks fine. From your experience do you think the salami has gone bad or have I just had good fermentation? Due to the enclosed chamber the smells will be more concentrated as oppose to drying in a larger area. What are your experiences with odors out of your curing chamber? I don't have a PH meter. As the drying progresses I expect the smell will reduce? Not sure if I should toss the lot or just see it through till the end. Any help greatly appreciated.

Victor @ Taste of Artisan says

Dallas, congratulations on the new setup! I don't recall smelling sulfur/rotten eggs on my salami, that smell isn't common, nor is it good. I think that indicates spoilage activity. I am wondering if what you perceive as sulfur may be the smell of ammonia. Ammonia smell is quite common. It happens when molds oxidize lactic acid, producing ammonia. Ammonia doesn't smell bad though, it' pungent but not terrible. Rotten egg smell is nauseating. If the smell makes you feel sick, that's a pretty good indication that the meat is spoiling. I had a couple of batches like that. Somehow, the meat meat got infected and by day 5-6 the smell was so revolting that I had to throw the whole batch away. So, use the smell as the queue.

I would recommend investing in a good quality pH meter to make sure you hit the target pH level, that's an important safety hurdle. 2.5% salt for traditional salami is lower than the recommended 3% - 3.5%. Salt is another important safety hurdle. You don't mention use of bacterial cultures and curing salt/nitrate. If you don't use those, it's easy to have spoilage bacteria take over and ruin your batch. Hope this helps and good luck!

Dallas Grgic says

Thankyou Victor for taking the time out to reply to my message. I'll purchase a PH meter and up the salt %. Also reduce the amount of capsicum sauce. Once again thankyou for the inspiration.

Victor @ Taste of Artisan says

You are very welcome. Please, check out my salami recipes, some of them are very detailed and I hope you find them helpful.

David Steel says

This is by far the finest article I've read about DIY curing chambers. I've been trying to hobble together a list of part and there it is. everything explained with the parts you used.

The internet is a God send for sharing information.

Thanks,

Dave

Wilmington, Delaware

Victor @ Taste of Artisan says

Hi David, I am glad you found my article helpful. Good luck with this hobby!

Mike Buser says

So you are using the actual compressor for the cooling....controlled by the controller and not the internal dial on the refrigerator?

You are using a heat mat to raise temp controlled by the controller. Am I correct so far?

Next question is, I see you are using a humidity controller for humidifying and dehumidifying.

You had links for both, but when I clicked on the links, I only saw the humidifier and controller. What are you using for dehumidification?

Victor @ Taste of Artisan says

If you want to look at it that way, yes. The external temp controller supplies or cuts the power to the fridge depending on the internal temp. So, as you put it, it pretty much controls the compressor coming on and off.

Yes, I use a heat mat to raise the temp during fermentation or drying.

No idea what happened to the link to the dehumidifier, I fixed it. I use the Eva-dry Edv-1100 Dehumidifier. I have two of them, one is enough for a 1-fridge setup but I sometimes use two when the batches are especially large.

William Alexander says

Victor your website and how to build rocks but I’m mechanically challenged. Plus I am So pressed for time. Do you have any sources you could recommend who sell curing chambers that are not the size of a large fridge? I’m looking for something the size of a wine refrigerator that has all the components built into it. I know given several days and hours of anguish I could maybe complete it myself but building things like you’ve outlined is a gift I was passed by on!

Victor @ Taste of Artisan says

William, I've never seen one like that, let alone a properly functioning one with those parameters. The smaller they are, the harder it is to control humidity in them and that is the most important thing. Your best bet would be Umai bags, which you can use to cure meats right in the fridge. Some people tried and swear by them. Easy. You should try and see how that works for you. Good luck!

Lorin Chak says

I've been using a wine cooler to age pancetta, as that was what I had. However it ruined my wooden floor because it dripped a lot of water. Someone on reddit said this problem could even kill the compressor because theres a humidifier inside adding extra moisture. I noticed you advocate a frost-free fridge. Is that precisely the fix to this problem?

Victor @ Taste of Artisan says

Lorin, a frost-free fridge is required because it effectively removes moisture from the chamber. A non-frost free one keeps it in, which makes it hard/impossible to properly control humidity inside the chamber.

As I mentioned above, in my post, I barely use a humidifier as I don't have a need for it with my setup. Meat in the ciuring chamber will be releasing enough water during drying to keep the humidity up. Even more so if using a non-frost-free fridge. At least in my climate. In very dry climates, it may very well be different. I'd add a humidifier only at the late stages when the meat is very dry and doesn't release sufficient amount of water into the chamber to keep the humidity up. The rest of the time, I use a dehumidifier only.

As far a water leaking on the floor, I can't answer that question as I don't know how your wine cooler works and how the rest of the equipment works. It's possible that your humidifier was working overtime and release too much water, or maybe the wine cooler was not operating properly, or something else was the problem. It's hard to say without a proper investigation.

Lorin Chak says

This is what someone on reddit said and the result of dripping water under the cooler matches my situation so I feel this is me, but was wondering if you can confirm: "The unit runs dry because the water will stick to the condenser during cold cycle then drip outside via the gutter underneath. With a humidifier inside, that will just create more ice on the condenser and it'll eventually lead to a dead compressor (happened to me!)."

I don't understand physics well but what sticks out is that my wine cooler also has a compressor. During my maturing phase I have it set to 50-57F, and targeting RH of 70-90 with my added humidifier. Sometimes after the compressor runs to cool down unit, I hear dripping underneath the unit, as I've placed a pan underneath to catch the water. I've bandaged the dripping of water for now but hope the compressor wont die. Let me know if I can clarify my set-up further!

Victor @ Taste of Artisan says

Lorin, humidity of 90 is too high. You should target 70-78 at the most, depending on the drying stage. It's actually a little more complex. Initially, the meat releases a lot of water so I drop the humidity even lower to keep up with the removal of extgra moisture. Once the water loss stabilizes, I go to about 75-78. Then drop to 72-75. The goal is to keep the surface slighly hydrated, not wet/sticky/dry.

What controls your humidity? The humidifier? Or do you have a separate humidity controller that controls the humidifier? I would recommend an accurate hydrometer to validate your RH levels. Do you really need a humidifier? As I mentioned before, I don't need one until the sausage is pretty dry. Most of the time, I need a dehumidifier to bring the humidity down.

Lorin Chak says

Thanks for digging deeper. So I have the inkbird temp controller, and the inkbird humidity controller hooked to the same eva-dry dehumidifier and a vicks humidifier. I have the drying phase down pretty well and it mostly focuses on the dehumidifying.

Then in the maturing phase, that is where I get this wine cooler leaking water from underneath and outside the unit where I have to use a pan to catch drippings. During this phase I mentioned I have RH set between 70-90RH (which you recommended for Pancetta). By the way 70-90 is a big range. I don't know if it matters so I have the difference values on the controller set at 80RH with ~5-7RH so actual values swing from 73-88.

Lastly I have been researching between frost-free and automatic defrost fridges. They are not the same but both supposedly do the same thing. For charcuterie, will automatic defrost work just as well?

Victor @ Taste of Artisan says

No worries. I am not an expert in how fridges work but it seems to me that auto defrost fridges may not have the same advantage as frost free where the moisture is constatnly removed. It seems that in auto defrost they let ice accumulate and defrost it at pre-determined intervals. If that's the case, battling humidity will still be a challenge. I did some partial drying / maturing in a small non-frost-free bar fridge and it was a huge challenge. However, that was a small fridge; they larger they are, the easier it is to manage humidity. I would still recommend going with a frost-free to make things easier. Much easier I should add.

Yeah, I see where you are coming regarding the humidity levels of up to 90%. I thought you were going that high for salami and solid muscles. 70-90% was described in the Pancetta Piacentina PDO. I imagine that may be the natural range of humidity in their cellars. I'd imagine 90% is more of occasioanl peaks, while the averages would be lower.

Try dropping the humidity to closer to 70%. Pancetta can take it easily and won't dry out. Also, dial down your humidifier's mist release. I recall having mine once set to high and I had condensation all of the chamber. That wasn't pretty. Can that be the case with your setup? Also, non-frost free fridges have drip trays underneath to catch water. Do you have one of those? If not, maybe you should add one to protect the floor. Hope this helps.

C says

If you don't drill holes into fridge how do you run all your cables from in to out? Does the multi air flow of this LG unit blow too much air onto meat causing case hardening?

Victor @ Taste of Artisan says

The cables run between the door and the fridge, as shown in the pictures. Here is a close up:

https://tasteofartisan.com/wp-content/uploads/2023/12/curing-chamber-1.jpg

As far as air flow and case hardening, it's no different than my previous two fridges. I am happy with it.

Victor @ Taste of Artisan says

For those of you who have been asking for an update on my curing chamber and more specifics about my current setup with part/model numbers, a diagram of how the components are connected, etc. - your wish came true. I updated the post with all the details and hope I addressed all of them. If I missed something that you wanted me to address, let me know in the comments below. Cheers!

Kevin says

Victor, I will pre apologize for this inquiry. I have read every word that you have posted several times and have only increased my confusion. Would you please repost your latest equipment (brand, model, what I it's use is)you are using for your chamber. I have some experience building this sort of equipment so I'm confident with the correct list of equipment the construction would need relatively easy. I have built controller boxes for all my smokers using all Auber electronics inc pid's . I would agree Auber products fall a bit short on calibration but they have always been available for help (sometimes communication is an issue tho). Price is not as important as a qualify set up(not wealthy but willing to go an extra 1/2 mile for quality. Thank you very much

Victor @ Taste of Artisan says

Hey Kevin, no need to apologize. If it's confusing, just ask. We all learn here. Some confusion may have resulted from the fact that I've updated and refined my equipment and the process many times to optimize it and perfect the results. I will update my post with the most recent equipment in the near future - like, I will do it by end of this month. Stay tuned.

Lorin Chak says

Not much is said about how to cool the fridge to exact temps such as 71 or 65F. Are we assuming the obvious that the fridge itself is connected to the temp controller to cool down when needed? I am using a compressor wine cooler and its temp can’t be dialed. Will connecting it to the temp controller damage the compressor if constantly triggered on and off?

Victor @ Taste of Artisan says

Yes, the controller will either initiate the fridge to bring the temp down or the heating pad to raise it. It's important to dial in the controller such that it cycles less frequently. The controller has a safety setting that prevents starting the fridge again within a preset time, usually 5 minutes to allow the compressor to decompress and hence prevent damage. There is always risk of damage of some sort, but that's the nature of this game game and that's why it's a good idea to get a used fridge for $50 - $150 bucks. I've been doing this for over a decade and I've used several fridges over that time; so far haven't had issues with compressors.

Darko says

Hello Victor,

Thank you for creating this article and sharing your very valuable experience on meat curing at home.

I have always wanted to make my own salami and pancetta and your article inspired me to dive in and give it a try!

I live in Florida so I will have to deal with high temperatures and humidity almost all year round. I am planning to install a fridge in the garage where the temperature ranges from 80F-100F and the humidity is up to 95%.

I love smoked meat and I was wondering if smoking the salami and pancetta first would help with the curing process?

I noticed that you have tested many different temperature, humidity and ph controllers over time. My hobby is electronic projects and I was thinking of building my own controller that would control temperature, humidity and ph, be programmable and send information and alarms to my phone. Over time, the software could be further customized to support different programs depending on the required meat curing process. There is also the possibility of developing a Temp/RH sensor that can be inserted into the salami to get real-time information on whether curing is progressing at a good rate or fridge temperature and humidity needs to be adjusted accordingly.

To do this I will need help with the fermentation/drying schedule that needs to be programmed into my controller. If you are interested in this project, please let me know and we can get in touch via email.

All the best and I look forward to hearing from you.

Victor @ Taste of Artisan says

HI Darko, welcome to my blog.

Hi temps and humidity aren't your frinds when it comes to curing meats but with a fridge, that's not that big of a problem.

Smoking meats and sausages before curing is not an unusual thing. Smoke adds flavor and also serves as a preservative. You'll notice that mold doesn't form on smoked surfaces or there is very little of it. That's about it. It's not going to aid in any other way that I know of.

Wow, that's an ambitious project. Real time measurting of temp/RH inside meat, ha? Meat temp can be calcualted by approximating the average temp in the fridge. Not sure how helpful it will be. PH inside meat? This won't apply here. You will need to measure Aw, or water activity. This is a common measure to assess the dryness of meat. Aw can be very different if meat dries unevenly, e.g. when there is case hardening. A good Aw meter is in the thousands of dollars. That's goon be a huge challenge.

Anyway, thanks for offer but between work, family, my blog and other commitments, it's going to be tough for me to find enough time for this project. But I wish you all the best, perhaps you will revolutionize home curing. Good luck!

Ken says

Good evening again Victor

Someone I saw and I am not sure if it was in one of your post or not, but a way to measure botulism with an electronic unit? Any suggestions? Thank you

Ken

Victor @ Taste of Artisan says

Hi Ken, I have never heard of such a consumer-grade device, but technically, it should be possible to measure the amount of b. toxins in meat.

Ken says

Good Evening

I have been doing smoking and making Salami from wild game for almost 10 years and trying to get into curing of some of the meat that I harvest. Thank you for your very informative post here. The frigerator that you use, is it a working fridge and do you run it to keep the 55-degree temp? Appreciate your help.

Thank you.

Ken

Victor @ Taste of Artisan says

Hello Ken, yes, this is a working fridge where you need to maintain 55F most of the time. The temp will be higher during fermentation and drying, and will gradually decrease to 55F for maturing.

Roger says

Hello Victor,

I am just getting started in the sausage game & was wondering if you could tell us exactly what you are using & how your humidity cabinet is set up. I was looking at the commercial ones & they are way to much money.

I came across your web page & thought "Brilliant".

Thanks in advance!!!

Victor @ Taste of Artisan says

Hello Roger,

I am putting on the finishing touches so to speak on my new two-fridge setup, which I will write about in the neat future. Meanwhile, it's all the same that I described in the post above. My setup includes a medium-size frost-free fridge, two Auberinc controllers - TD120-WIFI and HD220W, a peltier dehumidifier, an ultrasonic humidifier, a small seedling heating mat. That's it. Nothing special. If you have any specific questions, let me know.

Daren says

I'm doing a build right now. With the new Auber humidity controller, do you still recommend getting the Hannah hygrometer?

Thank you, I can't wait to get this up and running!!

Victor @ Taste of Artisan says

Hi Daren,

In my experience with Auber controllers, they are pretty accurate so no, a Hanna hygrometer is not needed. It's nice to have for double-checking but not absolutely required. Also, it helps to think of relative humidity as, well, relative. Say your meter says the RH is 75% but the meat surface is too wet and you observe excessive mold formation. So, you adjust the humidity until the surface of the meat is just slightly hydrated and the mold is a thin layer of white powder. It's nice to know that your 75% or 80% RH are true 75% and 80% RH, but in real application you'd need to make adjustments based on how the meat behaves.

MA Graffigna says

I have looked at alot of sites about these issues for curing. To-date yours has been the most straightforward and yo the point. I want to thank you for all of your time you spend sharing this information. I have been wanting to dive into curing for at least 2.5 years now. I feel like I can finally get started. Thank you so much and I wish you an even better future in curing. Michael G

Victor @ Taste of Artisan says

Michael, this is a very exciting hobby, good luck to you. I've had many hobbies over the years that came and went but this one has stuck with me for many years and I still enjoy it as much as I did in my first year. Thank you for the kind words. Curing cab be straighforward and relatively easy, I think I can say that by now, if you 'crack the code' so to speak. There is a lot of limited information and misinformation about curing on the Internet and many books too. I followed them and my results were hit or miss. It shouldn't be like that. The biggest thing that helped me produce consistent results was understanding the process. The second was to have the right equipment to support that process. Once I had both down, the rest of the pieces just fell in place.

By understanding the process I do not mean knowing the steps. That's what's wrong with most of the information/books on home curing - they just give you steps. I mean really understanding that the heck is going on under the hood. Fermenting at room temp and 100% Rh for 2-3 days, then curing at 55F and 75Rh rarely produced results that wowed me. Fermenting at decreasing Rh was a huge struggle and never really worked for me. The key was in the simple physics - rate of evaporation must equal rate of diffusion. I used to quote this myself but I never really understood it hence I never had a process in place to support it. But once I did, things changed in a big way. How that will work will depend on your setup and everyone's setup will be different. That's what it's also impossible to give a universal advice on this.

John says

Hi Victor! More questions for you please!

To start with, my home curing (based on your instructions for a chamber – thank you again) has been pretty successful to date and I have managed to produce one parmello salami and one chorizo. Both tasted great, and I followed your recommendation and bought a PH tester so felt a lot safer eating them!! However, whilst both were delicious, both were hollow even though I only went for 40mm casings – I evidently need to improve my stuffing skills as well as building that cold smoker! 😊

I now want to try something different! I have always loved merguez sausages, so thought I would try a merguez salami!! I have found a recipe but had always thought that lamb was trickier to cure; so, please, any tips/advice? Do you have your own proven recipe/Instructions/drying times?

And secondly – the ‘recipe’ I have calls for a B-LC-007 starter culture, which I’m having trouble sourcing in the UK. Alternatives seem to be the F-LC culture, the T-SPX one, or the Bessastart one that I have already used – but the question has led me to realise that I don’t know the pros and cons of each, or even the difference between ‘traditional’ curing and fast curing!! So – please – can you enlighten us all on starter cultures?

Thanks Victor! (And apologies if I have posted this to the wrong page)!

John.

Victor @ Taste of Artisan says

John, glad to hear about your successes. Hollowing inside, I think, is the result of one or a combination of insufficient mixing, not enough fat, loose stuffing, and insufficient trussing. You don't need to truss smaller caliber sausages but it helps.

Never tried curing lamb, maybe in the future I will, so can't advise you on that, not yet.

B-LC-007 is not my favorite. I've used it a few times, check out my Fuet recipe here on the blog, the sausage came out a little too acidic for my taste. I much prefer T-SPX as I like the taste of traditionally fermetned sausages. B-LC-007 has a number of bio-active protective properties but it's really not a substitite for T-SPX, it looks like it was designed for more quick-fermenting sausages. To me, it's more like F-RM-52 as far as resulting taste. If that's what you are after, sure, it's a good choice. Here is a good discussion on that. F-LC is simiar to T-SPX but ferments at wider temps (T-SPX is ideal for under 75F/24C), and has a bi0-protections against Listeria. Hope it helps.

Paul says

Hi Victor,

Can you plug both your humidifier and the dehumidifier into the one Auber HD220-W humidity controller, or do you need two controllers (one for each)?

Thanks,

Paul

Victor @ Taste of Artisan says

Hi Paul, yes you plug in both into the same controller. One plug is for humidifier, one for dehumidifier.

Paul says

Hi Victor, I just found your site and am loving it. I'm currently spending a month in the Dolomites and was so inspired by the speck that I decided I want to make may own when I get back home to the states. Thanks so much for sharing your knowledge and the details of your set up.

Question for you - do you think the Mini Big Green Egg would work? I'm not really ready to buy a new MiniMax Big green egg so I'm looking on FB marketplace and found a 7 year old mini that I could probably buy for $150. Wanted to see if you had any thoughts on using the Mini instead of the MiniMax. Thanks!

Victor @ Taste of Artisan says

Paul, you are talking about the smoking part, not the curing one, right? I guess your comment is more appropriate under the DIY smokehouse post. I don't know how you want to use it, but if your plan is to use it as I do, sure, you can use the Mini instead of MiniMax. I've had speck cold smoked, warm/hot smoked and fully cooked. All tasted really nice, though the texture was different.

Paul says

Oops. Yes, I was talking about the smoking part. Should have posted it there! Thanks for the reply!

Victor @ Taste of Artisan says

The most critical part is to supply good smoke. As with anything smoked, be it brisket or kielbasa, or speck, you want the proverbial 'thin and blue' smoke. Smoke that is clean and nice smelling, free of unburnt particles that carry unpleasant smell and bitter taste, which is not good for your health either. All green eggs that I've cooked with - large, medium and minimax, excel at producing amazing smoke once you learn how to use it. It's not hard but takes some getting used to.

Manuel says

Man, got my first batch of salame (salumi in my native spanish), coppa, bresaola and chorizo out of my first curing chamber project and I'm very happy with the results. Thank you so much for this post, has been a true guide and inspiration, specially on the basic principles of humidity management.

Victor @ Taste of Artisan says

Congratulations, Manuel. Happy to hear about your results. Enjoy! I am getting very close to finishing the electrical work in my basement and setting up my two new fridges. Can't wait to make a few batches of new things I have already planned. Chorizo sounds great, haven't made it in a while.

Manuel Campos says

I also skipped the drilling, packed the cables with duct tape, perpendicular to the gasket. No loss of temperature or humidity. I did two sets of cables, one for the appliances, another for the sensors, separated by about 60 cms.

Victor @ Taste of Artisan says

Thank you for confirming that, Manuel. I suspected that it would work fine. I just can't make myself drill holes in my new beautiful fridges that cost me a small fortune;)

My electrical cables are finally pulled, took me a loooooot of work, for the new fridges and for other purposes, hoping the electrician will install power outlets and connect them to the panel this week. Can't wait to test out my new setup.

Simone says

Good morning, how did you fit the cables in the fridge? Did you drill from the side or did you make a hole on the door? Did you seal the opening with silicon or similar?

Thank you for your help.

Regards, Simone

Victor @ Taste of Artisan says

Simone, in my first fridge, I drilled a hole in the door, that was an old fridge that I had used for beer/cider. It's not best way to do it as the cables are always in the way. In my second fridge, I drilled a hole in the side (make sure there is no piping or electrials there). The hole is covered with silver tape on both sides. I did not want to use silicone or something permanent as I experiment and tend to put things in and out through that hole.

In my newest setup - two new freezerless fridges - I don't feel like damaging them so I will be running all the cables through the door opening, with the door closing on them. The gasket is soft enough to wrap around them to create a nice seal.

Attila Nagy says

Thank you for your research!

Have you ever built a curing room? I'm thinking to convert a large container size walk in cooler. It's more challange to control humidity evenly in this kind of large space.

Any recommendation?

Best regerds: Attila

Victor @ Taste of Artisan says

Hi, you are welcome. No, I've never built a curing room/cellar... there was a discussion on this in the comments below if you search for it. I have a cold room and an unheated garage that I sometimes use for drying/maturing when the temps are acceptable but nothing more than that. Controlling temperature should be a little more challenging than in a fridge but doable. Controlling humidity by virtue of large size of the room should be much easier though. But the most important part is insulation and use of proper materials that don't absorb humidity easily. Insulation will stop humidity traveling in and out of the room. Good luck!

Gigio says

Hi! What a great work you are doing! Congrats!.

A few months ago I made my own Cure Chamber, but totally smart. I use some sonoff switches and sensors, allied to scenarios configured directly in Ewelink application, and can be connected to alexa, google home, but avoid this connections because sometimes the devices don't respond because they are in use in Alexa.

Next week I will replace the wifi sensors and switches by zigbee devices and connect to a home assistant local installation(to avoid the need of cloud service by internet).

Your chamber have a original cooler to distribute the cold air? I ask because my fridge have this and some pieces of salami who was putted to cure near of this cold air exit had case hardening.

Thanks for all your explanations, you have a good didatic.

Cheers

Victor @ Taste of Artisan says

Hi, that sounds really cool. I can't yet wrap around my mind around how I could automate my curing chamber but I am sure there are cool scenarios. I recently bought two new large freezerless fridges to completely revamp my setup but just need to put it all together. I need to run electrical wiring in the finished basement to plug in the fridges but that has been a bit of a challenge. Hope to finish it soon. Very excited about it.

Yes, in my chamber that's the original cooler. It's really nothing more than just an old fridge that I got second-hand. But it does the job well. Will probably be retiring it once the new fridges are up and running.

Mike S says

Thank you for the article, also waiting for an update. Wanna try to build curing chamber as well

Victor @ Taste of Artisan says

Mike, I have been crazy busy here so I am quite late but getting close. The preferred location of the new fridges has no power source so I am running new power cables and that's a challenge in a finished basement. There is nothing out of ordinary here with the new setup, except I got two larger 'all-fridge' fridges. One fridge is too limiting for me. Two will allow me to have one do primarily fermentation/drying (and maturing when needed and possible), the other one will be strictly for maturing or it can be used for fermentaion/drying as well when possible. That flexibility is what I've been missing.

Don says

It would really be great if you had a list of the things you ended up using after all of your experimentation. I'm just getting started and have to build something that can be used for my meat drying experiments and the wife's cheese making facination. I have read that these both use near the same environment so if Im going to buils something I want to have the best control I can.

Victor @ Taste of Artisan says

Hasn't changed much but I am redoing some things soon and will be posting an update in March. Nothing that would change how my setup works, just expanding it. For now, it's still the same frost-free fridge, an Auber temperature (heat/cool) controller, an Auber humidity (humidify/dehumidify) controller, a seedling heating mat, a Peltier dehumidifier, and an ultrasonic humidifier.

Compared to before, I don't use a humidifier at all until about a month - 1.5 months into maturing. There is plenty of humidity caused by water released from the meats until then. Once that water release slows down, I turn on the humidifier. Running a humidifier until then causes more problems than it fixes.

Meats and cheese should not be in the same chamber. The environmental requirements are similar but not the same. I've tried, it didn't work.

Nik Petro says

Did the March post happen yet? I tried to find an update. Just making sure I didn't miss it. Thanks, Love your site!

Victor @ Taste of Artisan says

It's on my to-do list. I have been very busy lately but I hope to finish the post in the near future.

John says

Hi Victor,

Firstly, thank you so much for such an informative, detailed, and fascinating site. I was recently challenged by my children to start making my own charcuterie, and so finding your pages has been a Godsend! I have only managed droewors and biltong so far, but my end goal is our favourite Hungarian winter salami / teliszalami so I am now graduating to Chorizo and an Italian parmanello as my next challenge whilst I build a cold smoker!

And so, please, can I pick your brains on one point? I have already built a curing chamber very much along the lines of yours (thank you again!!) but based on a wine fridge rather than a regular fridge. My thinking was that since it heats as well as cools and can maintain a steady temperature anywhere between 5C and 18C it would require one less external controller and no heating mat. BUT….. all of your recipes suggest dripping and drying temperatures (at least in the first few days) of up to 25C.

So …. Will it be OK to have a slightly longer drying time at 18C (until I hit the 16% weight loss mark) rather than starting at 25 and decreasing it to 18 over time - or will that harm the ‘fermentation’ process?

Thank you!

John in the UK

Victor @ Taste of Artisan says

Hi John,