Bergamo salami is known for its superb taste that makes it highly desirable. It's has a soft texture and a characteristic sweet, delicate, slightly spicy taste. This salami is difficult to buy outside the province of Bergamo and the best examples of this salami are still handcrafted. I've never had an opportunity to try the real deal, but I am determined to replicate this wonder-salami at home. There is nothing you can't cure at home with a good ol' meat curing chamber with fine-tuned temperature and humidity control.

Bergamo Salami, or Salame della Bergamasca in Italian, is native to the province of Bergamo in Italy. The origins of this salami go back to ancient times. After World War II, it was used as a formal means of payment in the region. In the whole province, it is the best known and most consumed type of salumi.

Making Bergamo salami

Bergamo salami is the product of the climatic peculiarities of the province of Bergamo, where the high humidity prevented the development of other cured meats, such as ham. As a result, locals created salami that could be matured even for a long time (over 90/100 days) in such conditions.

The meat

The peculiar climatic conditions also resulted in Bergamo salami using all the parts of the pig, even the noblest ones, which in other regions would be used for making ham, capicola, or culatello. As well, there was no need to add other types of meat, such as beef.

Another characteristic of Bergamo salami is that it uses meat that comes from a heavy, mature pig, fed exclusively with grains easily grown in the area, such as corn. Mature pigs are better for salumi production as they have a lower water content in muscles, which is ideal for dry-curing.

Bergamo salami consists of a 75-80/20-25 ratio of lean to fat pork. Traditionally, medium-grain sea salt is used at 2.3% - 2.5% of the total meat content. That said, in a home environment and especially when using commodity pork, I recommend using a minimum of 2.8% of salt.

The seasonings

The seasonings used to make this salami are very basic: black pepper, full-bodied red wine (e.g. Valcalepio), fresh garlic and nutmeg, cloves, cinnamon and mace. Fresh garlic in this recipe is only used to infuse wine and is discarded after the infusion. The amounts of spices are tiny, less than a gram, but they go a long way and only enhance the flavor of the pork. You will need to use a precision scale to weigh out the spices in grams, like this Precision Pocket Weight Scale.

Needless to say, it pays to use the best and the freshest pork you can find to make this salami, or any artisan salami for that matter. I learned that years ago when I made my first batch of Genoa salami. This time around, I am using Berkshire and Gloucestershire Old Spot mix that I purchased from Murray’s Farm.

The grind and the stuffing

The meat is ground through a large plate for lean pieces and a medium plate for fatty pieces, then stuffed in natural 70mm - 80mm casings. The length of the salami should be no less than 10 inches (25 cm) and each should weigh no less than 2.2 lbs (1.5 kg).

Drying and maturing

To make this Bergamo salami, I am using the new process that I've been experimenting with lately, and about which I wrote in the homemade capicola and pancetta posts. I've had much more consistent drying with it, no case hardening and improved flavor. It starts with what they call in Italy 'dripping' and goes into intensive drying over the next 6 days.

The drying schedule that I used is as follows:

| Stage | Duration | Temp | RH |

|---|---|---|---|

| Dripping | 14 hours | 77F (25C) | < 99 % |

| Drying | 17 hours | 73F (23C) | 75-85 % |

| Drying | 24 hours | 71F (22C) | 68-78 % |

| Drying | 24 hours | 68F (20C) | 65-75 % |

| Drying | 24 hours | 64F (18C) | 68-78 % |

| Drying | 24 hours | 61F (16C) | 72-82 % |

| Drying | 24 hours | 59F (15C) | 76-86 % |

The objective of the drying phase is to have the salami lose water as efficiently as possible without the casing drying out. During this initial period, salami loses a lot of water anyway and the higher temperature and lower humidity levels will ensure that the water loss is optimal while keeping the casing moist. Do not expect the water loss to be complete, such as 35% or higher, it will only range from 10% to 20% depending on the thickness of the salami.

The schedule above is tuned for thick salami (75mm and up), so you will need to make adjustments for thinner salami.

Salami weight loss progress

While Bergamo salami is typically stuffed into 70-80mm casings, mine was 130mm. With beef bungs, it's a common thing - one side is thicker than the other and some beef bungs are smaller than others. Anyway, this thick salami lost only 11.1% by the time drying was done and the rest of the water loss will occur during maturing.

| Weight, g | Loss, g | Loss, % | |

|---|---|---|---|

| Start | 2,303 | ||

| 3 days | 2,148 | 155 | 6.7 % |

| 5 days | 2,083 | 220 | 9.5 % |

| 7 days (end of drying) | 2,047 | 256 | 11.1 % |

| 12 days | 1,962 | 341 | 14.8 % |

| 23 days | 1,849 | 454 | 19.7 % |

| 1 Month | 1,806 | 497 | 21.6 % |

| 2 Months | 1,637 | 666 | 28.9 % |

| 3 Months | 1,539 | 764 | 33.17 % |

| 4 Months | 1,502 | 801 | 34.8 % |

| 5 Months | 1,444 | 859 | 37.3 % |

Maturing

After drying, the salami went into the meat curing chamber where it will slowly mature at 55F - 57F (13C - 14C) and 80% - 84% for 3+ months. In my case, as the salami is exceptionally thick, it will most likely take about 5-6 months to mature.

Starting, interim and target pH

The starting pH was at 5.79, which dropped to 5.09 by the end of the 7th day.

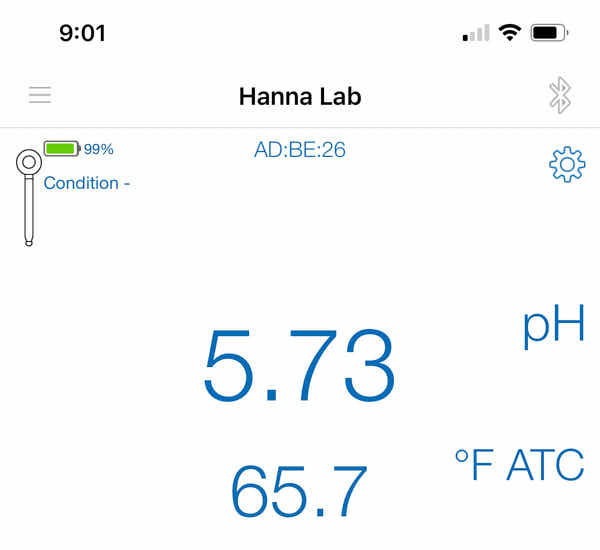

I expect the pH to continue dropping a little lower over the following 3 days, level off and gradually come back up. One of my favorite dry-cured sausages is Italian-made cacciatore. In addition to superb texture and flavor, it lacks the overwhelming acidity of the North American commercially produced fast-fermented salami. I checked it's acidity and got the reading of 5.73.

This is my ideal target pH but let's see what we get once my Bergamo salami is fully mature. It has developed a beautiful white mold which should help bring acidity down over time.

Tasting notes

Five months later my Bergamo is done and I happily cut into it. What a beauty!

Perfectly cured from side to side with no signs of case hardening. I could not be happier with the curing results.

Tastewise, it's quite good. Delicate and quite aromatic it was but not sweet as the PDO description described it. Perhaps by 'sweet' they mean not spicy, dolce as opposed to piccante. I detect just a hint of spiciness and noticeable aromas of mace, cinnamon, cloves and nutmeg. These spice aromas are quite potent and compete with the porky flavor. I wouldn't say that they overpower it but the aromatics are very noticeable. If you like aromatic salamis, this is a good one to try.

Time and time again I get reminded by my family members that they'd rather prefer smaller fat pieces. Fennel salami was perfect in that respect. If and when I make this salami again, I will grind the meat and the fat through a 3/16″ (4.5mm) grinder plate.

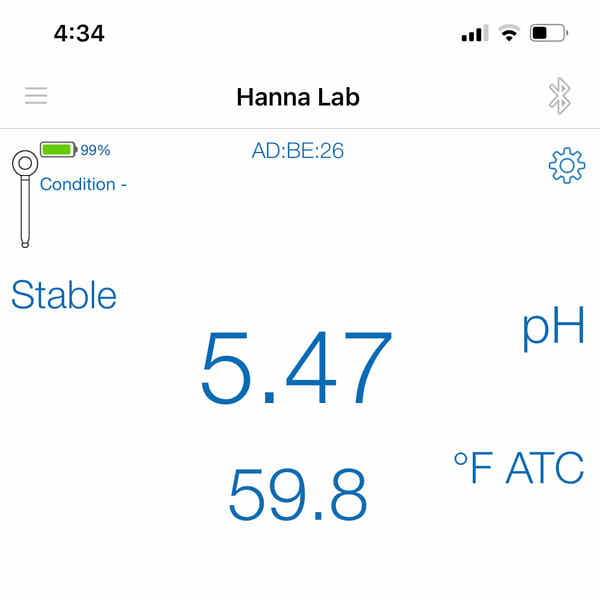

The final pH was 5.47 which translated into very mild acidity characteristic of traditionally cured Italian salami. I tend to favor salami with less acidity so this was a pleasant surprise.

Overall, this was a very good tasting salami. I can't say that it was the best I've ever tasted but it was very good and I am glad I tried it. Because of the strong aromatics, I think this recipe would be a good candidate for making salami with commodity pork which benefits from slightly stronger aromatics.

If I were to compare Bergamo salami against the other two most recent salamis that I made, Finocchiona (fennel) salami would be at the top, very closely followed by Calabrese salami, then followed by Bergamo. My family members by far preferred the Calabrese salami, one of our family's all-time favorites, closely followed by Finocchiona, then by Bergamo.

Ingredients

- 750 g lean pork any or a combination of ham, shoulder, neck (coppa), or loin

- 250 g fatty pork cheek, belly or back fat

- 25.5 g sea salt

- 2.5 g Cure #2

- 2 g dextrose

- 0.12 g T-SPX culture

- 60 ml distilled water

- 0.5 g black pepper cracked or split in halves

- 1/4 clove garlic crushed, for infusing wine only, removed after infusion

- 10 ml red wine Full-bodied red wine, e.g. Valcalepio from Bergamo or any other full-bodied red wine

- 0.5 g nutmeg 0.3 to 0.5 allowed

- 0.4 g cloves 0.3 to 0.5 allowed

- 0.3 g cinnamon 0.3 to 0.5 allowed

- 0.3 g mace 0.3 to 0.5 allowed

Instructions

- Crush the garlic and place it in a small cup. Add the wine and let it infuse for at least 30 minutes and up to 2 hours. Strain the wine before mixing it with the meat.

- Rehydrate the starter culture in 60 ml distilled water. (see notes)

- Weigh the lean meat and the back fat in grams. Calculate the rest of the ingredients, except the distilled water which will remain the same (see notes), weigh them out and set aside.

- In a small bowl, combine the salt, Cure #2 and dextrose.

- Cut the lean meat and the back fat into 1-inch pieces and place into separate bowls. Sprinkle about 80% percent to the salt mixture over lean meat, 20% over fat and mix each well.

- Freeze the meat and the fat for 20 minutes before grinding.

- Grind the lean pork through a 3/8-inch (10 mm) grinder plate. Grind the fatty pork through a 1/4-inch (6mm) grinder plate.

- Combine the lean pork with seasonings, dextrose, and starter culture. Mix well, until sticky, then mix in the groud back fat. It helps to use a stand mixer with a paddle attachment for this.

- Stuff into 70-80mm natural casings and tie into 10-inch (25cm) links, weighing not less than 1,500g.

- Using a sterilized needle or sausage pricker, prick holes across the entire salami.

- Weigh the salami, write down its weight on a tag and attach the tag to the salami.

- If desired, inoculate with mold.

- Use the leftover meat from the stuffer/stuffing tube to make a small sample for measuring the initial pH and the pH at later stages. Make sure to record the readings.

- Dry at 59F - 77F (15C - 25C) and 65% - 86% RH for a period of 7 days as per the drying protocol above. Measure the pH, it should be below 5.3 at this point.

- Mature in the curing chamber at 55F - 57F (13C - 14C) and 80% - 84% for about 3 months.

Alternative curing method

- Ferment salami at 68F-70F for three days to get the pH below 5.3.

- Cure at the standard 55F-57F and 75% RH until 35% weight loss is obtained.

Notes

Nutrition

JUANQUI. says

Hi VICTOR.

Recientemente hice un embutido muy sencillo (chorizo español) :

Paleta de cerdo 792 grs.

Tocino 239 grs.

Nitrito 0.154 grs.

Sal 21 grs.

Pimenton 20 grs.

Ajo 2 dientes, los incorpore machucados junto con el vino.

Vino tinto 30 cm3.

Maduracion 3 semanas....Mi pregunta es porque se formo un hueco en el centro del embutido...color rojo clasico y sabor suave al no tener pimientas y otros condimentos.

Agradeciendo tu respuesta saludote atte.

Juanqui.

Victor @ Taste of Artisan says

Hi Juanqui, I will respond in English, please use Google translate. The holes in the center of the sausage is most likely the result of uneven drying. You want to make sure that when drying/maturing, the surface of the sausage is constantly moist, but not wet or dry. This problem can also be, fully or partially, the result of insufficient mixing and/or loose filling. Try to fill it very tightly, prickle the surface then truss very tightly to remove any air pockets inside. Hope this helps.

esb says

looks fantastic, thanks

but it feels like there is more than 25% of fat judging by the picture

also it says "each should weigh no less than 2.2 lbs (1.5 kg)"

2.2 lbs is just 1 kilo

regards

Victor @ Taste of Artisan says

Yeah, looks like more fat but it's exactly 25%. The 1 kilo / 2.2 lbs is for reference. You weigh your meat then figure out the weight of the ingredients. Say your meat is 2,350g then you need to multiply the ingredients by 2.35.

Tijana Bodiroga says

Hi

Can I make it without using Cure #2

dextrose

T-SPX culture

I dont think I can find these things where I live.. thanks

Victor @ Taste of Artisan says

You could, but I would not recommend it.

Norbi says

Hi Victor!

Can you help me please...

Is it normal that my salami is at 37 % weight loss, the humidity in my chamber varies between 76-86% RH, it's been 7 weeks since I put it in there but it still feels soft when applying pressure? Did I mess up something or should I just need to be patient and wait a bit more?

Victor @ Taste of Artisan says

Hi Norbi, what's the diameter of your salami? If it's around 110-130 mm, a 37% weight loss in 7 weeks is way too fast. If it's 70-80 mm, it's still fast but not too bad. In either case, it looks like the outer parts dried a little too fast and the center dried at a slower pace. Bring the humidity closer to 80% - 82% if you can and let it mature for another month or two and it should be fine. If you can't control the humidity and it continues at 76% - 86%, just let it mature longer, eventually, it will firm up. Mind you, this is a soft salami, so don't expect it to become very firm.

Norbi says

Thank you for the quick answer! I used 50 mm diameter casings.

Btw I can control the humidity, it just tricks me all the time, cause I measure different values at different points of the chamber (modified fridge)...

Victor @ Taste of Artisan says

I see. Try going by look and feel rather than just the hydrometer readings. The casing should feel hydrated but not wet, sticky or slimy. It should not be dry. If you see only white mold, the humidity may be a little low. As the humidity rises, white mold will bloom resulting in the appearance of a green tint. It will be bright green which will turn darker/dirtier green over time. Check out my post on green mold for more details. I've had better results maturing thicker salami at higher humidity where green mold is inevitable. This applies to the maturing stage, after the initial drying is done. Too much humidity initially will cause all sorts of issues. Too little humidity later on will cause uneven drying. Keep checking it every couple days and adjust as needed. As one very wise Italian sausage maker once said - salami is like a baby, it needs constant attention. Good luck!

Glenn Bearden says

Hi Victor,

I have been looking through your posts trying to find the actual PH meter you are using. Could you send me the actual model number.

Thanks

Glenn

Victor @ Taste of Artisan says

I have three, but I surmise you are interested in the one that allows for the screenshots of the measurements that you see in this and some other posts. It's the HI10532HALO Wireless pH Meter.

Rob says

Victor, what adjustments to the drying schedule would you recommend for thinner salami - say 40 mm? Thanks.

Victor @ Taste of Artisan says

For thinner salami, 5 days of drying will suffice. The max temp 68F-70F, gradually dropping over the 5-day period. Humidity ranges - I would increase those by 2 percentage points compared to thicker salami.

JUAN CARLOS. says

Extraordinarias recetas para quienes gustan de practicar la charcuteria casera.

Victor @ Taste of Artisan says

Muchas gracias, Juan.