Until now, my experience with making Salame Toscano (Tuscan Salami) has been limited to Michael Ruhlman's recipe which I did many years ago. It was a fast fermenting, tangy salami that included dry milk powder. It tasted good but wasn't something I was eager to repeat. A few years later, I got a chance to taste PDO (Protected Designation of Origin) Salame Toscano which left a lasting impression. I can best describe it as a delightful medley of flavors in the mouth. You can only get this kind of taste and soft texture by using excellent pork, skilful use of seasonings and proper aging. So, here goes my attempt to replicate this fantastic salami at home.

I am using Salame Toscano PDO description as a guide for my recipe. Unlike PDO descriptions for some other salami that provide a lot of details, this one is quite skimpy so I had to fill in a few blanks.

According to the official description, it is made of lean parts of the pig (ham, shoulder, neck) that are finely chopped/ground and combined with the fat obtained from the dorsal region and cut into cubes. The meat is mixed with seasonings (salt, peppercorns, red wine, garlic and sugar) and is stuffed into pork or beef casings.

The salami that I tried seemed to have a small portion of the fat ground while the rest was cubed. I am going to do take the same approach here. To season it, I am going to use salt, pepper, red wine, garlic and dextrose, as recommended. Note that I am not adding fennel which I know many Tuscan salami recipes do. It's not a required herb in the PDO description, I didn't taste it in the salami that I am trying to replicate, and I want the flavor of fennel to stay unique to Finocchiona salami, another favorite Tuscan salami of mine.

Salame Toscano matures from 20 days to 12 months depending on the size of the salami. After the fourth month, the larger sausages are treated externally with fat which allows for a longer seasoning, which results in a richer flavor. The formation of mild mold on the outside is an indication of authenticity.

Making Salame Toscano

To make this salami, I am using Berkshire / Gloucestershire Old Spot pork that I purchased from Murray’s Farm. The meat comes from a mature pig and has a dark red color; it should make great salami. The best artisan salami in Italy is made from mature pigs weighing at least 350 lbs (160kg). Their meat contains less water and is therefore much more suitable for charcuterie.

Seasonings

The amount of salt to use in salami has always been a challenge for me. Sure, I can follow Marianki's 'safe' recommendation of at least 3% for traditionally cured sausages, but that's just too much salt. I like my sausage way less salty. I use only 1.3% for fresh sausage. Looking at the PDO description of Salame Piacente, their guideline is between 1.5% and 3.5%. Given that my pork comes directly from a small farm, I feel more comfortable using less salt, about 2.1% to be specific. If I were to use commodity pork from a grocery store, I wouldn't go lower than 2.8%.

The rest of the seasonings are a small amount of a combination of whole and ground black peppercorns, and a little bit of red wine infused with garlic.

The idea of garlic-infused wine as opposed to using garlic itself came from the making of Bergamo salami. Upon research, many Italian salami makers use this technique and add no actual garlic in salami. Some artisan salami makers even use the 'garlic hands' technique as they call it. What they do is rub hands with a crushed garlic clove then mix the meat. This way salami acquires just a hint of garlic aroma without becoming 'garlicy', like my Fuet did.

Some Tuscan manufactures add herbs to bring more aromatic flavors but I chose to keep this salami traditionally simple as I am using good quality meat and want the pork flavor to dominate and be just slightly enhanced by garlic, wine and pepper aromas. Good meat, salt, pepper and a dash of good Tuscan wine followed by long and slow aging in a cool humid environment is all that's necessary to make fantastic Salame Toscano.

Griding the meat and stuffing

The grind in Salame Toscano is fine, I went with 3/16" (4.5mm) grinder plate for both the lean meat and the small portion of the back fat. The rest of the fat I cut into small cubes.

After mixing, the meat was stuffed into beef bungs and tied into 10" - 12" links.

Drying

In the past, I would ferment salami at 68F-70F for three days to get the pH below 5.3, and cure at the standard 55F and 75% RH until 35% weight loss. This is a good approach, so use it if you are more comfortable with it and have had good results with it.

Lately, I've been using a slightly different approach designed to optimize drying during the first week. This may seem counterintuitive but it makes sense if you think about it. Salami loses a lot of water during the first week so why not create an environment that makes the process optimal? Not only does this create another hurdle against harmful bacteria development, but it also reduces the risk of case hardening based on my experience.

For thicker salami (75mm – 110mm), I use the following schedule:

| Stage | Duration | Temp | RH |

|---|---|---|---|

| Dripping | 14 hours | 77F (25C) | < 99 % |

| Drying | 17 hours | 73F (23C) | 75-85 % |

| Drying | 24 hours | 71F (22C) | 68-78 % |

| Drying | 24 hours | 68F (20C) | 65-75 % |

| Drying | 24 hours | 64F (18C) | 68-78 % |

| Drying | 24 hours | 61F (16C) | 72-82 % |

| Drying | 24 hours | 59F (15C) | 76-86 % |

Maturing

After drying, the salami went into the meat curing chamber where it will slowly mature at 55F – 57F (13C – 14C) and 80% – 84% for 3+ months. Note the higher humidity level here.

Starting and finishing pH

The starting pH was at 5.79, which dropped to about 5.10 by the end of the 7th day.

I expect the pH to continue dropping a little lower over the following 3 days, level off and gradually come back up a little.

Salami weight loss progress

Below is the weight loss progress of my 90mm and 110mm salami using the new drying technique.

| #1 (90mm) | Weight, g | Loss, g | Loss, % |

|---|---|---|---|

| Start | 1,929 | ||

| 3 days | 1,756 | 173 | 8.9 % |

| 5 days | 1,667 | 262 | 13.5 % |

| 7 days (end of drying) | 1,619 | 310 | 16 % |

| 12 days | 1,520 | 409 | 21.2 % |

| 23 days | 1,374 | 595 | 28.7 % |

| 1 Month | 1,321 | 608 | 31.5 % |

| 1.5 months | 1,226 | 708 | 36.7 % |

| #2 (110mm) | Weight, g | Loss, g | Loss, % |

|---|---|---|---|

| Start | 1,920 | ||

| 3 days | 1,758 | 162 | 8.4 % |

| 5 days | 1,683 | 237 | 12.3 % |

| 7 days (end of drying) | 1,637 | 283 | 14.7 % |

| 12 days | 1,548 | 372 | 19.4 % |

| 23 days | 1,409 | 511 | 26.6 % |

| 1 Month | 1,367 | 553 | 28.8 % |

| 2 Months | 1,204 | 716 | 37.3 % |

Tasting notes

The thinner Tuscan salami lost almost 37% of the green weight after 6 weeks and I decided to cut into it. It's a little sooner than I had anticipated but it felt firm enough. Interestingly, both this one and the thicker Tuscan salami felt quite a bit firmer than the other salami that I made at the same time: Bergamo, Calabrese, or Finocchiona. This must be related to the coarsely chopped fat which allows water to more freely escape the meat. The way this salami has been drying is noticeably different from the other salami.

Quicker water loss is not necessarily a good thing. It's harder to manage. The outer parts tend to firm out quicker and the center stays softer. This requires a more involved humidity level management to control the 'diffusion and evaporation rate' equilibrium. So, in the future, I will be drying and maturing this type of salami separately to ensure that I can tailor the drying and maturing conditions specific to this type of grind.

The salami has a rich taste with light peppery notes. There is an intense and wonderful aroma of aged pork not overpowered by spices. There is barely a hint of garlic. The mouthfeel is rich and creamy, with a mild tang. I like the aftertaste - pleasant, lingering, with a slight tang and a barely detectable pepper bite. This is the kind of salami you want to savor, like good wine.

The coarsely chopped fat in this salami appears visually overwhelming but as soon as you put a slice in your mouth you don't feel like there is too much of it. Instead, it provides the desired creaminess and richness. I like how the fat tastes in this salami, it's very mild. It's pure white. It's soft but has texture and no greasiness. If you look at my Spanish Fuet that I made recently using commodity pork, you will immediately notice the difference.

My wife doesn't like chunky fat pieces in her salami so she didn't want to try it on its own, but with a slice of bread, she said it was excellent.

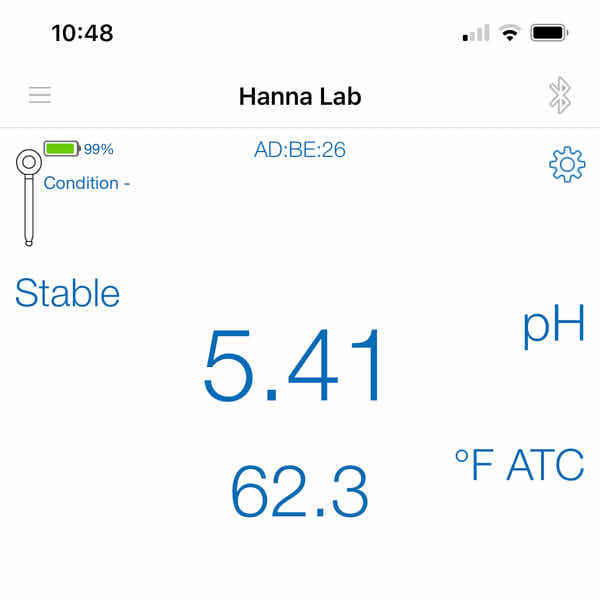

The salt level is perfect - I used 2.1% salt as I had mentioned above. It could've been even a little higher with no problem. The pH bounced back to 5.41 which I found to be quite pleasant.

Overall, I am very happy with the results. It's not easy to say exactly how this salami compares to the PDO Salame Toscano that I wanted to replicate without a side-by-side comparison, but I'd say it's pretty close. I am also quite happy with the new drying and maturing process. It's not easy to cure thick salami at home but the new process definitely made it easier for me.

Was there a notable difference in taste and in flavor between heritage pork and commodity pork salami? Yes. There is a noticeable difference. Don't get me wrong, salami made with regular pork is very good. It tastes better than most charcuterie from the supermarket. That said, salami made with heritage pork is something else. It's smoother, creamier and nicely porky. It doesn't need a lot of species to have a rich, intense flavor. The color is also richer and darker.

Ingredients

- 750 g lean pork any or a combination of ham shoulder, neck (coppa), or loin

- 250 g back fat belly or back fat

- 25.5 g sea salt

- 2.5 g Cure #2

- 2.25 g dextrose

- 0.12 g T-SPX culture

- 60 ml distilled water

- 20 ml red wine good Tuscan red wine

- 1/4 clove garlic crushed, for infusing wine only, removed after infusion

- 3 g black pepper whole

- 3 g black pepper coarsley ground

Instructions

- Crush the garlic and place it in a small cup. Add the wine and let it infuse for about 30-60 minutes. Strain the wine before mixing it with the meat.

- Rehydrate the starter culture in 60 ml distilled water. (see notes)

- Weigh the lean meat and the back fat in grams. Calculate the rest of the ingredients, except the distilled water which will remain the same (see notes), weigh them out and set aside.

- In a small bowl, combine the salt, Cure #2 and dextrose.

- Cut the lean meat and about a 1/4 of the back fat into 1-inch pieces. Cut the rest of the back fat into small cubes, keeping separately. Sprinkle about 80% percent to the salt mixture over lean meat with large back fat pieces, and 20% over the finely chopped fat and mix each well.

- Freeze the meat and the fat for 20 minutes.

- Grind the lean pork and the larger fat pieces through a 3/16″ (4.5mm) grinder plate.

- Combine the ground pork with seasonings, dextrose, and starter culture. Mix well, until sticky, then mix in the groud and the cubed back fat. It helps to use a stand mixer with a paddle attachment for this.

- Stuff into 70-110 mm natural casings (beef bungs) and tie into 10"-12" links.

- Using a sterilized needle or sausage pricker, prick holes across the entire salami.

- Weigh the salami, write down its weight on a tag and attach the tag to the salami.

- If desired, inoculate with mold.

- Use the leftover meat from the stuffer/stuffing tube to make a small sample for measuring the initial pH and the pH at later stages. Make sure to record the readings.

- Dry at 59F - 77F (15C - 25C) and 65% - 86% RH for a period of 7 days as per the drying protocol above. Measure the pH, it should be below 5.3 at this point.

- Mature in the curing chamber at 55F - 57F (13C - 14C) and 80% - 84% for about 3 months.

Alternative curing method

- Ferment salami at 68F-70F for three days to get the pH below 5.3.

- Cure at the standard 55F-57F and 75% RH until 35% weight loss is obtained.

Notes

Nutrition

Pavel says

Hi! what mixer do you use to mix the minced meat

Victor @ Taste of Artisan says

I use a KitchenAid Commercial 8qt stand mixer.

Jim says

I stuffed mine in 40mm casings. After 24 hours, my ph was 5.32. Now , at the 48hr mark, it is sitting at 5.41. Should I be concerned? Or, should I continue fermenting?

Thank you!

Victor @ Taste of Artisan says

It looks to me like one or both of you pH measurements are incorrect. Ph in sausage isn't likely to jump from 5.32 to 5.41 in 24 hours. Ph in traditionally cured sasuages, such as this one, will slowly drop over 10-12 days, then very slowly recover to about 5.4 by the time the salami will fully mature, as a result of interaction with Penicillium nalgiovense and/or Penicillium salamii molds. In other words, you need white mold and some time to have the pH rise like that. I'd carefully check it again in several sample places and go from there.

Angelo Foce says

Hi I haven't tried this recipe but definitely will. Most of my salami has a light bitter taste how can I avoid this, otherwise my salami is very good.

Thanks

Angelo

Mario says

Hi there..

I've tried your recipe before, and the salami came out delicious! I'll be doing it again... but looking to make much more.

I'm looking to make approx. 9 kg of meat for my next batch. You mention to double the water if we go over 3kg of meat. Since I'm making around 9 kg, do I need to double the water volume again after the 3 kg? For example, do I need to increase water amount to 360 ml if I'm doing 9 kg? Or do I keep the water at 120 ml, and just increase the amount of starter culture?

Thank you!! Looking forward to seeing how the new batch comes out!

Victor @ Taste of Artisan says

Hi Mario,

technically, you could increase the amount of water leanearly - e.g. double or triple the water when doubeling or tripling the meat. However, I've noticed that I get a perfectly good distribution of seasonings and starter without increasing water that much. The idea is to get rid of the water from salami so adding more water is kind of counterintuitive and increases the risk of growth of pathogens, so I try to keep it to the minimum. But the starter culture should increase linearly. For 9 kg of meat, I'd start with 180-240 ml of water. Add more if the mixture feels too stiff to properly distribute the seasonings.

Mario says

Hi Victor,

Thanks for the reply. I ended up going with ~150ml of water. And thanks for the tip on the water content. I didn't think about that.

PH dropped to below 5.3 in about 2 days. Let them ferment for 1 more before I threw them into the drying chamber. They look great! Although I did make a few larger sizes..around 19" in length. Hope that doesn't pose a problem for the finished product.

Would be great if we could share photos of our projects 🙂

Thanks again for the input and access to great recipes!

M

https://tasteofartisan.com/wp-content/uploads/2023/10/salami-1.jpg

https://tasteofartisan.com/wp-content/uploads/2023/10/salami.jpg

Victor @ Taste of Artisan says

Hi Mario, glad all went well. You can email me your photos and I will attach them to your comment. Unfortunately, there isn't a way for readers to upload pictures but I will happily do it.

Ph drop will continue into the drying stage so you can stop fermentation right at 5.3. You will notice that it will continue dropping further and eventually will come back up as the salami matures.

The length and the diameter of salami shouldn't pose a problem as long as it dries evenly. It can get a bit tricky with thicker/longer salami but keep an eye on it and flip if one end get drier than the other.

Good luck!

Victor @ Taste of Artisan says

Thank you for sharing pictures, Mario. Looking great!

Julian says

Hi Victor,

I'm about to start my salami journey with this recipe but I want to test it with thinner casings (34mm and 46mm) can I still apply the drying process describe above in your recipe?

Stage Duration Temp RH

Dripping 14 hours 77F (25C) < 99 %

Drying 17 hours 73F (23C) 75-85 %

Drying 24 hours 71F (22C) 68-78 %

Drying 24 hours 68F (20C) 65-75 %

Drying 24 hours 64F (18C) 68-78 %

Drying 24 hours 61F (16C) 72-82 %

Drying 24 hours 59F (15C) 76-86 %

Or would you apply the classic fermentation process?

In case of going with your drying method are these values valid for thinner cases?

Thanks a lot for your work and keep documenting everything. It's really helpful 🙂

Thanks!

Julian

Victor @ Taste of Artisan says

Hi Julian,

Classic fermentation process can mean so many things... I've read many traditional recipes from Italian forums/books/blog posts, they talk about hanging meat/salami to drip/ferment in a warm room, near a fireplace, with good air movement. Then they move it to a cooler place to dry before it goes to mature in a cellar... Or is it classic American sausage book 55F/75%RH? Or perhaps a stepped approach where you start at 100% RH and fermentation temp, finish fermentation while decreasing the RH, then cure at 55F/75%RH? Which one did you have in mind?

The process that I am using sort of replicates and improves upon this old Italian way of curing meats. Instead of fermenting by a fireplace, you do it in a curing chamber at optimal fermentation temps and humidity, then gradually drop the temp and humidity while the meat releases water. Once the water stops gushing out, your then mature at a level temp/humidity. How is it different from the American sausage book method? Well, it explicitly accounts for the fact that meat releases a lot of water during the first few days. This water needs to be removed such that the surface is neither too dry nor too wet. Usually, the surface will be too wet, leading to slime/stickines on the surface and the smell of ammonia, and bad molds. I've had those issues before, just like many others.

So, to answer your questions... You can follow any approach as long as you keep 'the rate of diffusion = the rate of evaporation'. I.e. the water that comes up the surface of the meat evaporates quickly enough not to cause it to be too dry or too wet. This can be achieved by a combination of airflow, humidity, temperature. There are many ways to do it... the stepped approach that I use is just one of them and the most consistently successful method that I've used.

The values above are more for thicker salami. For something in the 34-46mm thickness range, I'd drop the fermentation temp to 73F and shorten the ferm time to about 12 hours. I'd also shorten the drying cycle to about 5 days.

Good luck!

Julian says

Thanks a lot Victor. I'm going to follow your procedure as it makes more sense to me and will configure my Auber devices as follow:

Stage Duration Temp RH

Ferm. 12 hours 73F (25C) < 99 %

Drying 12 hours 71F (23C) 75-85 %

Drying 24 hours 69F (22C) 68-78 %

Drying 24 hours 67F (20C) 65-75 %

Drying 24 hours 64F (18C) 68-78 %

Drying 24 hours 61F (16C) 68-73 %

Maturing xx hours 55F - 57F (13C - 14C) and 73-75%

I took these values from the Salami Sticks recipe that you recently published. Does they make sense in your opinion?

I should consider the fermentation process finished when the pH reaches 5.3?

Thanks a lot 🙂

Victor @ Taste of Artisan says

Julian, I can't say I am an expert on this, still experimenting and trying to figure things out... so take what I say with a grain of salt.

Fermentation will not conclude in 12 hours nor should it be completed by the time that pH drops to 5.3. No wonder the Italians call it dripping, a very precise description of that stage as the liquids are literally dripping off the meat. I changed it to fermentation as it's more understandable here but really, it's just the start of it. The first step is to have the meat warm up all the way to the center to bring it to the temp where lactic acid bacteria begins to work. That's why we need warmer temps and longer times for thicker sausages there and less for thinner ones.

If you are using traditional fermentation (T-SPX, etc.) your pH will reach 5.3 in several days. I've published my numbers in one of my posts, I think in one case it was after 10 days. It dropped even further as maturing progressed and then recovered to 5.29 or so as it matured. Quick fermenting sausage (F-RM-52, etc) will reach that in 12-24 hours at the right temps (85F - 95F). The former needs more salt but gives a much nicer taste, the latter needs less salt but will be very acidic in comparison, and matures faster.

Those values will work for your salami but keep an eye on the sausage. Like I said, you want the surface to feel hydrated but not wet, or dry. If you see that something is off, adjust the rH up or down. Your setup will be different than mine, your readings may be different the mine so it's always best to keep a close eye on the sausages during drying. At maturing stage, you may want to start lower but bump the rH to 76-78 or the surface may dry too much. I find that when I start at 75-76%, there is still too much moisture being released so I drop it to 73% or so, and a couple of weeks later bump up to 75-76... Of course those values are relative as I let the humidity fluctuate a few percentage points up and down..

Anyway, as one old Italian sausage maker once said - salami is like a baby, it needs constant attention. I couldn't agree more. It's not a set it and forget it kind of thing if you want truly good results.

Cyril Meurillon says

Thank you Victor! I do notice the small air gaps by the oxidation areas. I will try to do a better job at stuffing and trussing on my next batch.

I otherwise really like the Toscano -- after 3-4 months, deep flavor of fermentation, nice kick from the black pepper and subtle flavor of garlic. Some friends got a little turned off by the size of the fat chunks, but that's all to my benefits 🙂 Definitely worth trying again!

And thanks also for the pH meter tip. I didn't see the meat testers, but I'll get the FC2022 as recommended because it seems more versatile and I may end up picking other food hobbies 🙂

Merry Christmas!

Victor @ Taste of Artisan says

Lol, that's a slippery slope... So, let me tell you where I use my pH meters now - beer making, cheese making, salumi making, canning and preservation, fermented foods, just to name the most common ones. It's quite rewarding though. Homemade kefir is out of this world. Fermented pickles, sauerkraut are... well, let me just say nothing store-bought even compares after you try them.

Merry Christmas!

Cyril Meurillon says

Hello Victor,

the salame toscano turned out to be delicious. However I ran into one issue: there is some discoloration and small air gaps in places -- but the flavor is very good, no funkiness. I would attach a photo here if I could. I used large beef bungs. No such issue with my other salami (finocchiona) which is in smaller casing (beef middles). In your experience, what are the most common reasons for this issue?

- bad stuffing? (I did my best to eliminate all air gaps during the process)

- large fat pieces in this type of salami?

- bad maturation or aging? (but why no issue with the finocchiona?)

And last question: I can see from your photos that you are using the HALO pH meter from Hanna Instruments (here https://www.hannainst.com/halo). Several types of probes/tips are being offered for different material. I see 2 for food: FC2022 and HI10532. Which one do you recommend? It might be helpful for others to add this to your equipment recommendation (great advices for the grinder and sausage stuffer!).

Thanks and very Happy Holidays!

Cyril

Edit - picture added.

https://tasteofartisan.com/wp-content/uploads/2021/12/SALAMI-BROWN-INSIDE-OXIDATION-RANCID.jpg

Victor @ Taste of Artisan says

Hi Cyril,

Sorry to hear about your challenges with the salame toscano. I will email you for the pictures. Based on what you described, looks like the salame wasn't stuffed or trussed tightly enough and some air pockets remained. This often leads to oxidation/rancidity of meat and fat which is accompanied by yellowish/brownish coloration. There is no foul odor initially and the sausage is fine to eat, it's more of an appearance issue. Eventually, the rancidity will become more apparent and you probably won't like it.

Another cause could be improper fermentation. This is often the case with thick(er) salami. One of my readers sent me some pictures where the area around the center was brown. We discussed this back and forth and agreed that his salami did not spend enough time at the optimal temperature to warm up all the way to the center so what happened was that the center didn't ferment properly and probably got overtaken by spoilage bacteria. To be honest, I've had a couple of those incidents happen to me too. The meat didn't smell good either so it got tossed.

No, I don't think fat size or maturation would play a role in that. Though, if the meat is not mixed well, the pieces won't stick together well enough and can separate during drying, leaving gaps that could lead to oxidation. Just an idea but I don't recall that happening to me.

Good idea about equipment recommendation... perhaps I will create a separate page where I will list all my favorite equipment - it will be a very long list 😉 - and where to buy it, I think many will find it useful.

As far as the pH tester model, I have the HI10532, along with another 2 Hanna pH testers, oh boy... That's quite a selection of wireless HALOs they have now. I recall when buying mine there was only one model that was more or less suitable for my needs. They say that the HI10532 is for semi-solid foodstuffs but I've been successfully using it to test salami and other cured meats without an issue. The tip is thicker though and leaves a bigger hole... If you make a cut with a knife first it's very easy to insert this tip. The tip on the FC2022 is smaller and is more pointy, and looks more like the one on my HI981036 which is specified for meat testing. If I were facing your choices today, I'd pick the FC2022.

Victor @ Taste of Artisan says

Thanks for sending the picture, Cyril. I've seen this a number of times and had this same issue in one of my thick salami as recently as one year ago. It was only one out of a batch of 6-7 that got this problem. What happened is that it got untied on one end while hanging in the fermentation chamber so I had to carefully remove some meat and re-tie it. I guess I didn't do a good job of making the meat tight and some air got introduced and which later caused oxidation which spread about an inch inside. Other times it was caused by loose stuffing. I can see on the picture that the meat is packed somewhat loosely and all those air pockets are causing oxidation all over to varying degrees. The best way to prevent that is to stuff very tightly, prickle the surface with a needle all over, then truss tightly, which will expel any remaining air out, hopefully. Otherwise, your salame looks very good, it's a shame that oxidation messed things up.

Cyril says

Very, very inspiring recipe! Thank you Victor!

I am ready to start and noticed step 8 states "Combine the ground pork with seasonings, dextrose, and starter culture. Mix well, until sticky, then mix in the groud back fat. It helps to use a stand mixer with a paddle attachment for this."

Should it read "then mix in the finely chopped back fat" instead?

Also, do you recommend using a sausage stuffer for the beef bung (~10cm), or by hand?

Thank you for confirming!

Victor @ Taste of Artisan says

Hi Cyril, it should have said 'then mix in the ground and the chopped back fat'. Updated.

I think it's ideal to use a stuffer as you can stuff the meat very tightly, eliminating any air pockets. If you do it by hand, without good experience, you are bound to get a few air pockets which will ruin the salami. Not just aesthetically, but taste-wise too as those areas will get oxidate and become rancid.

Cyril Meurillon says

Thank you for the recommendations, Victor! Salami is now drying. Now the hardest comes: resist the temptation to try it before it is ready 🙂

Victor @ Taste of Artisan says

No problem. My solution is to throw a few thin sausages in the mix, those are ready in 4 weeks or so. Good luck, hope they turn out great.

robert says

Great recipes , i was wondering if i did not want to use red wine or white , what is a good substitute? non alcoholic is what im aiming for, would red wine vinegar be used?

Victor @ Taste of Artisan says

Robert, simply omitting wine is a good option. You don't need to substitute. I've made many salamis without any wine and they tasted very well. Many Italian PDO salami recipes call for very little wine, so little that you can barely detect it in the final product anyway.

Ron says

Excellent recommendations. Thank uyou

TonyS says

Honest, clear description. Lots of tricks I didn't know. Thank you very much.

I would apprieciate a more detailed spice description for the supermarket meat.

Victor @ Taste of Artisan says

Hi Tony, you are very welcome. You don't need to go crazy on spices for supermarket meat. You won't get that rich color or porky flavor from commodity pork but it will still taste quite good. If I were to use this recipe with commodity pork, I would substitute the ground black pepper for 3 grams of white pepper as it adds a lot of aromatics, and double the amount of red wine. If you like fennel, add 2 grams of ground fennel or a gram of fennel pollen. You will like it I am quite sure.

Abraham Moyano says

The salami Toscano looks delicioso.

I should try making it done time.

Joseph Sanchez says

the salami Toscano look's great would like to buy this but no info on how, a or if you sale it

…. would like more info on this

Victor @ Taste of Artisan says

Hi Joseph, I am very flattered but I don't sell my salami, this is just a hobby, I am not licensed to sell food. But whereabouts do you live? I may be able to suggest some places.